Most people hear “product information management” and think of marketing. It’s the system that feeds websites, e-commerce platforms, catalogs, and customer channels with clean, accurate product data. And that’s true, but it’s only part of the story.

Product information management (PIM) shouldn’t begin when the product is ready to launch. It should start when the product is first being built.

When R&D teams contribute to and access product content early, it prevents breakdowns later in the process. Teams stop chasing specs and launch materials stay in sync with product changes, which means that errors drop, speed improves, and the entire organization benefits.

What Is PIM?

Product information management refers to the process and system used to collect, store, manage, and distribute product data. This data includes:

- Product names and descriptions

- Dimensions and weight

- Technical specifications

- Regulatory details

- Images and documents

- Pricing and SKU details

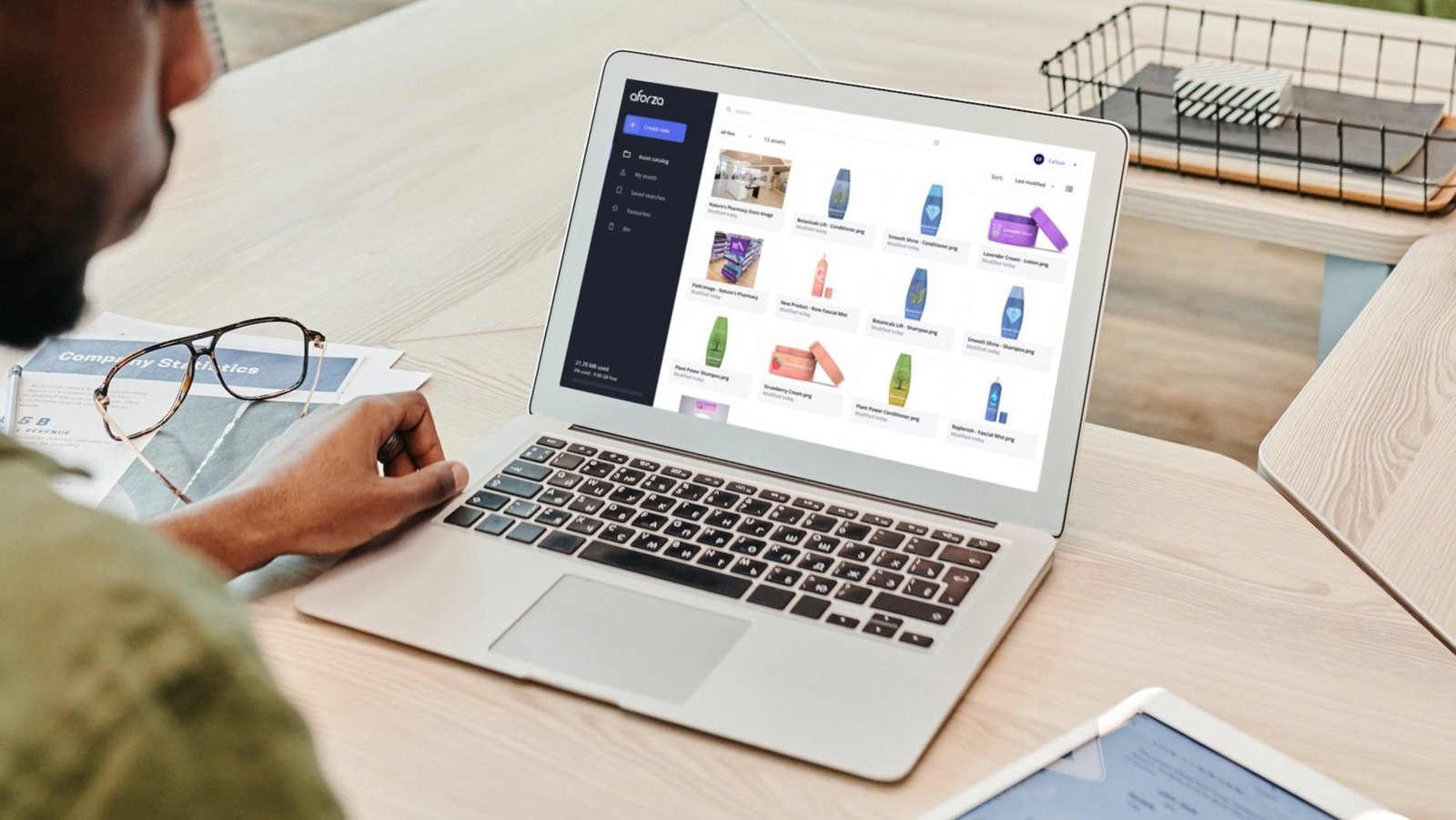

Product information management software creates a single place to manage this content. It sees that what appears on a website, in a catalog, or in a sales pitch matches the product’s actual nature.

Traditionally, marketing owns the PIM system. They use it to manage the final version of product content before a product reaches customers.

But if the process only starts that late, it introduces risk.

The Problem with Downstream-Only PIM

When a new product is developed, details constantly evolve. Specs may change, features may be added or removed, or packaging shifts. Without shared visibility, marketing, e-commerce, or sales teams often work from outdated or incomplete data.

This leads to:

- Mis-labelled products

- Wrong product images in promotional material

- Conflicting information between teams

- Delays from last-minute updates

Even worse, the product might go live with incorrect information, which can cause confusion, customer complaints, or returns. By involving R&D and product teams earlier in PIM, companies avoid this disconnect. They create a smoother handoff, faster launch timelines, and fewer surprises.

How Early-Stage PIM Improves Product Development

Involving upstream teams in the PIM unlocks several benefits:

- Version Control Starts Early

Product specs often go through several iterations. Having a centralized platform from the beginning means changes are tracked, approved, and stored in one place. No more digging through email threads or outdated PDFs.

- Launch Assets Stay in Sync

As development progresses, marketing can begin drafting packaging, web pages, and campaigns using live data. When product details change, those assets get updated automatically with no need to rebuild everything at the last minute.

- Regulatory Content Gets Built in

Many industries require specific product labeling or compliance documentation. When those requirements are tied to the product record from the start, they’re less likely to be missed or rushed at the end.

- Product Teams Get Insight into Customer Content

PIM isn’t just about what goes out to customers; it’s also about how that content is received. Teams can analyze which specs get the most attention, what content helps drive conversion, and what support materials customers use most. That feedback loop can inform future design choices.

Example: Industrial Equipment Launch

A company building industrial sensors has a product team working in CAD and PLM tools to finalize the design. Meanwhile, the marketing team needs specs, certifications, and descriptions for the product catalog and website.

If those two groups don’t share access to a common product information management software, the risk of mismatch grows. The product name may change late in development, but marketing still uses the old version. This means that a spec update may not reach the sales team in time.

By having engineering log updates directly into the PIM system, marketing and sales always have accurate data without needing to ask or manually sync files.

Aligning Teams Without Adding Work

One concern about bringing more teams into a PIM process is overhead. No one wants to create duplicate work or manage another tool.

Modern PIM platforms are built to integrate, not isolate. They pull data from PLM, ERP, and other systems. This means R&D teams can contribute without switching tools or entering data twice.

At the same time, product marketers get access to real-time information. They don’t have to guess which file is final. They don’t need to chase down engineering for approvals. Everything flows into one record, which can then feed every channel.