Where M35 is Essential: Critical Applications and Tooling

M35 isn’t used for simple tasks; it is reserved for the toughest jobs where performance cannot be compromised. Its superior characteristics make it the go-to material for environments demanding high-stress and high-production machining.

Tools for Difficult-to-Machine Materials

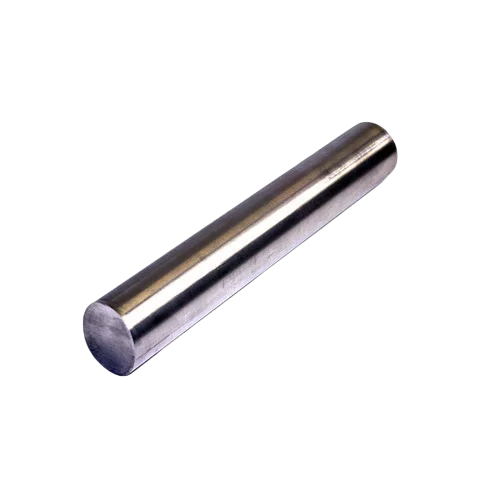

M35 is the ideal choice when confronting the challenges posed by high-tensile steels, difficult nickel alloys (like Inconel), and aerospace-grade titanium. These materials generate immense heat and place severe abrasive stress on the tool edge. Key tools critically reliant on the strength and thermal stability of high speed steel m35 round bars include:

- Twist Drills & Reamers:

- Application: Used extensively in the aerospace and defense industries for deep-hole drilling where precision is critical.

- M35 Benefit: They are vital for deep drilling applications where heat is extreme. The cobalt in M35 prevents the cutting tips from softening and failing prematurely, drastically reducing the risk of in-process tool breakage in expensive workpieces.

- Milling & Hobbing Cutters:

- Application: Necessary for intricate tasks like gear manufacturing and complex contouring in the automotive and energy sectors.

- M35 Benefit: M35 ensures that the critical edge integrity is maintained even when subjected to high impact forces and sustained high feed rates, guaranteeing dimensional accuracy across long production runs.

- Cold Work Punches & Dies:

- Application: Used in precision stamping and forming operations.

- M35 Benefit: The material’s exceptionally high compressive strength is utilized to prevent plastic deformation or catastrophic failure, ensuring consistency in formed parts over millions of cycles.

- Broaching Tools:

- Application: Used for cutting internal keyways and complex internal shapes.

- M35 Benefit: Due to the massive surface area contact and high cutting forces, M35 provides the necessary blend of toughness and hardness to handle deep cuts efficiently in single-pass operations.

Making the Right Choice: M35 vs. the Competition

When choosing tool steel, manufacturers often compare M35 against other common HSS grades. M35 consistently proves itself as the best balance of performance and economy.

M35 vs. M2 High Speed Steel (The Standard)

M2 is the industry benchmark, but M35 is the clear performance upgrade:

- M2 (Economical/Toughness Focus): Lower hot hardness, best for general-purpose applications and slower cuts. If the cutting temperature stays low, M2 is cost-effective.

- M35 (Speed/Heat Focus): Significantly higher hot hardness due to cobalt. This translates to an easy 15-20% increase in cutting speed over M2, leading to major productivity gains in high-volume settings.

M35 vs. M42 High Speed Steel (The Ultra-Performer)

M42 contains almost double the cobalt (around 10%) and is often called “super HSS.”

- M42 (Maximum Hardness Focus): Achieves the highest attainable hardness but is more expensive and generally exhibits lower toughness. It can be prone to chipping in applications with poor machine rigidity or intermittent, shock-heavy cuts.

- M35 (Balance Focus): Offers an optimal balance of very high hot hardness, excellent wear resistance, and sufficient toughness. It is the more reliable, durable, and often more cost-effective choice for general high-performance tooling where stability is a concern.

Sourcing Excellence: Partnering with a High Speed Steel M35 Round Bars Supplier

For sophisticated industrial buyers, sourcing is about more than just a purchase order; it’s about forming a strategic partnership. The right high speed steel m35 round bars supplier provides certainty, quality, and logistical efficiency.

Standards, Certification, and Traceability

Absolute material integrity is non-negotiable. Look for a supplier who guarantees:

- International Compliance: Materials certified to global standards like ASTM A600, DIN 1.3243, and JIS SKH55. This ensures consistent quality across different markets.

- Mill Test Certificates (MTCs): These are mandatory. Compliant with standards like EN 10204 3.1, MTCs verify the exact chemical composition, heat-treated properties, and non-destructive testing (NDT) results for every specific batch.

- Full Traceability: Every bar should be traceable back to its origin and manufacturing batch. This is critical for audits in high-stakes industries like aerospace.

Logistics and Global Reach

For a global enterprise, the supplier’s logistical prowess is as important as the steel itself.

- Expert Export: As referenced by a reputable supplier must demonstrate expertise in international logistics, including custom-specific packaging (e.g., specialized rust protection for sea freight), handling complex customs documentation, and arranging optimized transport to industrial hubs worldwide.

Conclusion: The Uninterrupted Flow of Quality and Performance

By partnering with a specialized high speed steel m35 round bars supplier, manufacturers are not simply procuring a commodity; they are investing in the guaranteed consistency and metallurgical excellence required at the cutting edge of industrial operations. A reliable supplier ensures that every bar meets the precise standards necessary to maximize tool life, safely boost machining speeds, and ultimately, secure a competitive advantage through enhanced overall operational efficiency. The choice of supplier is, therefore, a strategic decision that directly underpins the operational excellence of high-performance tooling manufacturers worldwide.