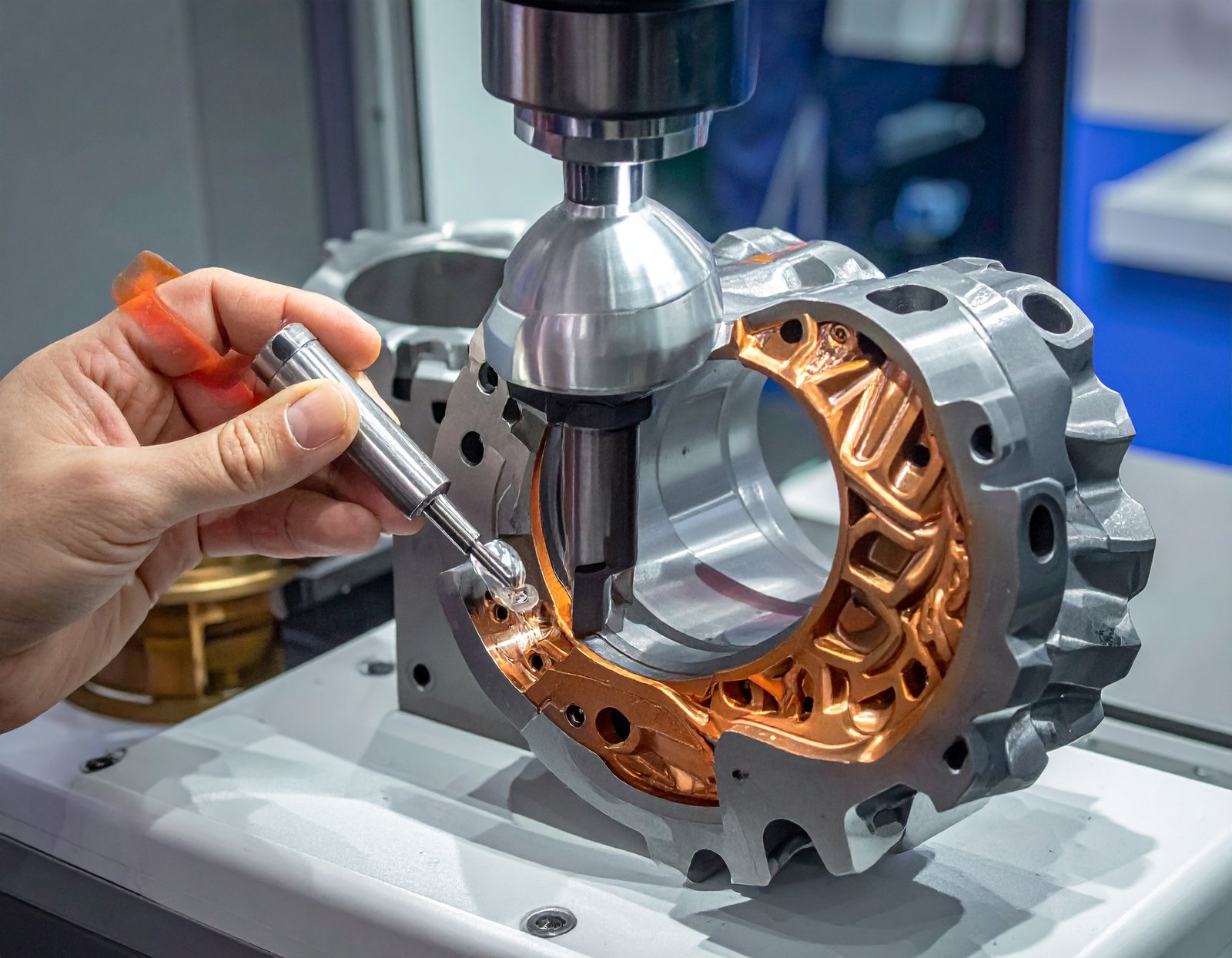

High-risk industries such as aerospace, automotive, and defense require components that perform with absolute reliability. Material selection and manufacturing processes play a vital role in ensuring performance under demanding conditions.

In such scenarios, CNC plastic machining services emerge as a preferred choice for many. Engineers choose them for their distinct advantages over traditional materials and methods.

Why Engineers Use Plastics Instead of Metals in CNC Prototyping

For years, metals dominated high-performance engineering. However, advanced engineering plastics now offer unique advantages:

- Lightweight and Corrosion-Resistant: Plastic components significantly reduce weight without compromising strength, making them ideal in applications where minimizing mass is critical. They resist corrosion from chemicals and moisture, which can degrade metal counterparts over time.

- Thermal and Electrical Insulation: Many plastics offer superior insulation properties, which are essential in high-risk environments with electrical or thermal exposure. This reduces risks associated with heat conduction or electrical faults.

- Chemical Resistance: High-performance engineering plastics withstand a variety of aggressive chemicals, acids, and oils. This extends component lifespan in harsh conditions where metals might corrode or weaken.

Key Benefits for High-Risk Applications

Plastic CNC machining provides advantages that are especially valuable in high-risk industries. Some of these notable perks include:

- Reduced Human Error and Enhanced Safety: Automation using CNC machines eliminates much of the variability associated with manual processes. This ensures parts meet exact specifications while CNC enclosures and automation improve operator safety.

- Improved Product Reliability: The tight precision and material consistency reduce defects that could cause failures in critical applications such as aerospace, automotive, or heavy machinery.

- Material Versatility: CNC plastic machining accommodates a wide range of engineering plastics, including PEEK, nylon, and acetal. Each of these materials offers specific thermal, mechanical, or chemical resistance.

- Smoother Finishes and Better Fit: Optimized machining parameters and finishing passes provide superior surface quality, essential for component performance and longevity in demanding environments.

Industries Leveraging CNC Plastic Machining

Several industries rely heavily on CNC plastic prototype machining for mission-critical projects:

- Automotive: Lightweight plastic parts reduce vehicle weight, improving fuel efficiency and performance without sacrificing durability. Components such as gears, bushings, and seals undergo CNC rapid prototyping to withstand mechanical stresses and chemical exposure.

- Aerospace: CNC plastic components meet stringent aerospace standards requiring low weight, corrosion resistance, and exacting precision. This works well for components like insulation parts and complex structural elements.

- Marine and Heavy Vehicles: Parts exposed to harsh weather and chemicals benefit from plastic’s robust resistance properties. This ensures longevity and safety in challenging environments.

- Industrial Machinery: Conveyor guides, valve seats, and other wear-resistant components rely on CNC-machined plastics for durability under continuous load and motion.

Future of CNC Plastic Machining in High-Risk Fields

As material science continues to advance, plastics with enhanced heat resistance, strength, and chemical tolerance are emerging. Precision plastic machining has proven its value in environments where precision and performance are non-negotiable. Its ability to produce accurate, reliable, and durable components makes it an essential choice for engineers in high-risk applications.

In search of reliable CNC plastic machining services? Contact Global Technology Ventures Inc. to see how CNC plastic prototyping can support your next high-performance project.