LED, optical, and intelligent lighting now illuminate most contemporary factory floors. It enables improved sight, safe working areas, and reduced power waste every day. The correct lens maintains the beam form consistently, even under severe setups. It remains steadfast, fog-free, and transparent throughout full work shifts and load.

The support from industrial lens manufacturers helps cut delays in the build or test stages. Design-to-delivery service ensures that the lens ships in good condition and fits properly. Most lens builds currently require dust seals, glare blocks, or UV guards. It provides users with smooth light without scatter or a chance of short life.

The development of AI software and machine vision increases demand even more. Each light requires a lens that is appropriate for both case and beam angle. It is cost-, time-, and waste-saving when the lens match system must be fast. Many expert teams at industrial lens manufacturers guide custom shapes, grades, and fits.

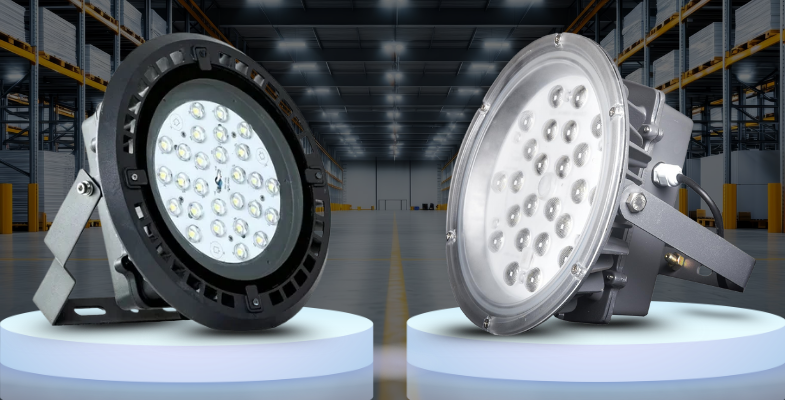

Full Range of Lens Options

There are spot, dome, oval, and beam styles available for every application. Each provides an unobstructed focus with reduced scatter or shadow problems. A broad lens scatters light over large surfaces without loss or glare. Some styles eliminate bright spots while increasing reach in tight spaces.

Oval is best for belts, sensors, or line lights on robots. The lens remains stable in frames and does not tilt or shift. It is comfortable in tight units. Industrial light lens types can also manage heat in long work hours. The grade does not change shape under heat, stress, or excessive force.

They offer improved light cut-offs for clear zone illumination. It remains scratch-free when operated in dusty or oily applications. The lens remains clean even as LEDs operate under maximum power. Each component is tested for durability, fit, and extended work life. The custom grades correspond to high-heat areas such as weld shops or test lines.

The glass remains haze-free and performs perfectly in both heat and cold. Dome designs distribute gentle light across work areas with minimal power consumption. Flat lens fits are ideal for safety lights or floor illuminating beacons. The customised industrial lighting setups often pair a strong lens with smart control parts. These lenses have important functions in scanners, vision tools, or LED rigs.

It enables companies to achieve beam objectives without wasting light and energy. The construction and fit do not flicker and remain in line at all times. A quality supplier provides an assortment of lenses with immediate delivery and support.

Lens for Harsh Use and High Heat

It resists UV, IR, shock, oil, and high-speed tool areas. The lens retains shape and holds up even in heat and extended runs. It remains strong where rapid work or high beams exert heat pressures. The component secures solidly with a clip or seal base for protection. It resists fog, grease, and sharp impacts from tools or conveyor taps. This keeps lights clear and bright even in metal-cutting areas.

Many industrial high bay lens manufacturer designs these to suit plant and floor heat loads. They use proven grades that won’t crack, cloud, or bend with time. It provides a solid base that prevents slipping or fragile beam angles. Some even function close to weld sparks or blast-clean gear lines. It maintains full clarity in long heat cycles, day or night shifts.

The construction eliminates light loss and prevents edge burns close to LED cores. Every lens type is appropriate for task lines, load zones, or high bay rigs. The grip system prevents shake, slide, or incorrect beam spread during operation. A seal base prevents dust, oil, or chip intrusion close to the lens. The custom high bay LED lights lens match needs where glare and heat must stay low.

The form and construction improve fit and protect the light within. Most lens manufacturers provide free trials, samples, and size adjustments upon request. They check for cracks, warps, or edge defects in initial runs.

Custom Lens for Smart and Sensor Gear

Some smart equipment, such as barcode scanners, OCR software, and AI devices, requires accuracy. It emits sharp beams with high CRI, minimal blur, and no haze. The lens prevents scatter, so scans remain in focus during rapid cycles. Types correspond to sensor range, view angle, and short case forms. It remains secure without shift, flicker, or edge misread during intense usage.

Engineers from industrial high bay lens manufacturer teams build these for tight beam control needs. A tight fit prevents stray light or signal distortion from improper spread. The focus remains constant despite unit movement, vibration, or heating. The lens provides complete clarity to smart gear in dimly lit areas.

Tech units with custom high bay LED light lenses get better scans and fewer misses. The design fits into case slots without compromising on sealing against dust or blur. The custom constructions help in scanning deep stacks, curved pieces, or reflective code stickers. It has a good pairing with IR tools and intelligent control systems.

Bulk Lens Supply and OEM Orders

High-volume lens runs reduce unit cost and error rates quickly. It maintains a stable production level while fulfilling bulk orders with precision. The batches are sealed, dated, and coded for traceability and packed densely. It aids in the easy assembly processes. Orders may include customised tags or be part of complete unit sets.

It is appropriate for brands requiring quick scale with no setup or fit concerns. Services from industrial light lens manufacturers include full OEM and white-label options. Each shipment is tested for crack, spread, glare, and grip strength. Delivery is made on time with sorted lots and part mapping to ensure clarity. They allow quick beam width change or base types where necessary.

All components fit end specifications without any gap in seal or fit. The engineers of customised industrial lighting often depend on such a steady lens supply. It keeps building flow quickly without concern regarding shape or loss. The grip and base are tested for push-fit or screw-lock type. It assists in achieving stringent timelines with zero part shape compromise.

Conclusion

The correct lens enables tools to operate with complete focus and minimum light waste. They prevent scatter, reduce harsh glare, and increase work clarity. Many industrial lens manufacturers ensure better grip, clarity, and fast design flow. The batch undergoes testing for fog, heat shift, and light control. It maintains lens use smoothly without a reduction in beam over time.

Some challenging work areas require heavy-duty lenses that won’t break or slide. They assist sensors and viewing tools to scan more quickly with smooth light lines. Batch-ready lens designs are now used by many for quicker supply cycles. The parts from expert industrial lens manufacturers bring tested strength and beam stability.

The improved lens support generates fewer defects and more floor output. Most now opt to receive both built value and long-term benefits.