In the vast field of material science, selecting the right metal for a project is one of the most critical decisions an engineer or designer can make. The choice impacts everything from structural integrity and longevity to cost and manufacturing efficiency. Among the myriad of available options, aluminium alloys stand out as materials of the modern age. And within this versatile family, Aluminium 6061 has earned its reputation as a true engineering workhorse, prized for its exceptional balance of properties.

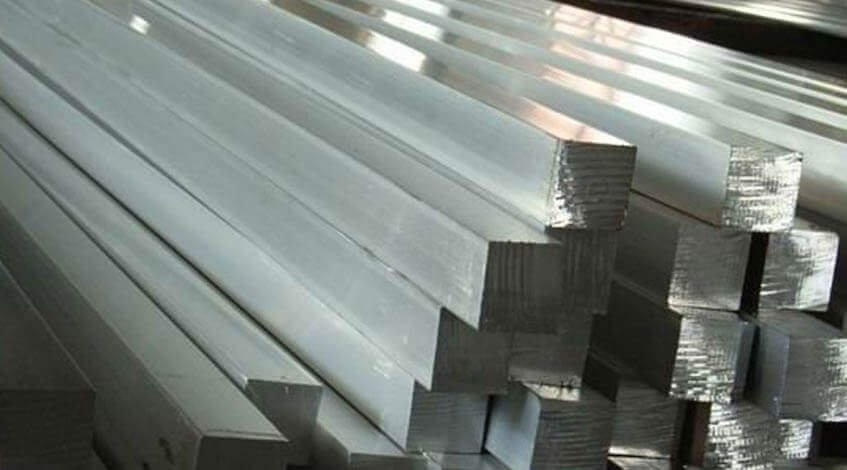

When this reliable alloy is formed into a fundamental shape like a square bar, its utility expands even further. Aluminium 6061 square bars are foundational components in countless industries, serving as the backbone for everything from complex machinery to everyday consumer products. This article offers a deep dive into the chemical makeup, key properties, and widespread applications that make this material an indispensable choice for projects worldwide.

The Chemistry Behind the Performance: What is Aluminium 6061?

At its core, Aluminium 6061 is a precipitation-hardenable alloy. Its primary alloying elements, magnesium (Mg) and silicon (Si), are the secrets to its success. During the heat-treatment process, these elements combine to form magnesium silicide (). This compound is what gives the alloy its significant strength increase after being subjected to heat and aging.

To appreciate its unique position, it’s helpful to see where it fits within the broader aluminium family:

- 2xxx Series: Uses copper as the main alloy, resulting in high strength but lower corrosion resistance.

- 5xxx Series: Uses magnesium, known for excellent corrosion resistance, particularly in saltwater.

- 7xxx Series: Uses zinc, producing some of the highest-strength aluminium alloys available.

The 6xxx series, and 6061 in particular, finds the sweet spot. It doesn’t have the top-tier strength of a 7075 alloy, but it offers far better corrosion resistance, formability, and weldability, all at a more accessible cost. This balanced profile is why it remains one of the most popular extruded aluminium alloys.

A Deeper Look at the Key Properties of Aluminium 6061

The theoretical benefits of an alloy only matter if they translate into real-world performance. Aluminium 6061 delivers on its promises through a combination of mechanical and chemical properties that make it incredibly reliable.

Excellent Strength and Durability

Aluminium 6061 provides a medium-to-high strength level, making it suitable for a wide range of structural applications. Its properties are significantly enhanced through tempering. The most common temper is T6, which signifies that the material has been solution heat-treated and then artificially aged. This process optimizes the formation of magnesium silicide, pushing the material to its ideal strength characteristics, with a typical ultimate tensile strength exceeding 42,000 psi (310 MPa).

Superior Corrosion Resistance

One of the standout features of this alloy is its ability to resist corrosion. When exposed to the atmosphere, Aluminium 6061 instantly forms a thin, dense, and passive layer of aluminium oxide on its surface. This layer acts as a barrier, protecting the underlying metal from moisture and other corrosive elements. This makes it an excellent choice for outdoor structures, marine components, and any application where long-term exposure to the elements is a concern.

Outstanding Weldability and Joinability

Ease of fabrication is a major selling point for 6061. You can readily weld it using common techniques like Tungsten Inert Gas (TIG) and Metal Inert Gas (MIG) welding. For the best results, use filler wires such as 4043 or 5356. Keep in mind that welding creates a heat-affected zone (HAZ) that slightly reduces the material’s strength, but engineers understand this effect well and account for it during the design phase.

High-End Machinability

Aluminium 6061 is known for producing good chip formation when cut, drilled, or milled, making it a favorite for machinists. This quality allows for the creation of components with tight tolerances and smooth surface finishes. Its predictable behavior makes it perfectly suited for high-precision CNC (Computer Numerical Control) machining processes.

The Practical Advantage: Why Choose a Square Bar?

While Aluminium 6061 is available in many forms, the square bar offers distinct structural and practical advantages. Its simple geometry provides four flat, stable surfaces, which simplifies mounting, drilling, and joining. Unlike round tubes or complex profiles, square bars can be easily aligned and fastened together to create robust and precise frameworks. This geometric efficiency makes them an ideal choice for support structures, braces, and foundational components.

Widespread Applications Across Industries

The combination of balanced properties and a versatile shape has led to the adoption of Aluminium 6061 square bars in nearly every major industry.

- Construction and Architecture: In building, these bars are used for structural framing, support columns for canopies, window and door frames, and architectural railings. They provide the necessary strength without the weight of steel.

- Automotive and Transportation: The push for lighter, more fuel-efficient vehicles makes 6061 a prime material. It’s used in chassis components, suspension arms, truck bodies, and frames for buses and railway cars.

- Marine Engineering: Beyond simple fittings, 6061 square bars are used to construct durable boat lifts, docks, masts, and booms, where their resistance to saltwater corrosion is invaluable.

- Industrial Machinery: For manufacturers, the predictable strength and easy fabrication of aluminium 6061 square bars make them indispensable for creating robust jigs, fixtures, conveyor frames, and automation equipment components.

- Consumer Goods and Sporting Equipment: Look around, and you’ll find 6061 in high-performance bicycle frames, scuba tanks, durable camera mounts, fishing reels, and the casings of premium electronics.

Finishing and Surface Treatment Options

To further enhance its properties or aesthetic appeal, Aluminium 6061 can undergo various surface treatments. Anodizing is a popular choice, as it thickens the natural oxide layer, dramatically increasing corrosion and wear resistance while allowing for the addition of vibrant colors. For other applications, powder coating or painting can provide a durable, protective, and decorative finish in any imaginable color.

The Go-To Material for Modern Innovation

From its fundamental chemical composition to its real-world performance, Aluminium 6061 has proven itself time and again. It offers a winning combination of strength, light weight, durability, and workability that few other materials can match. When delivered in the practical and stable form of a square bar, it becomes one of the most versatile and valuable building blocks for modern engineering and design.

For sourcing high-quality aluminium and other metal products for your next project, you can get in touch with Jagdish Metal.