In the world of industrial packaging, one material stands out for its strength, versatility, and cost-effectiveness—HDPE Woven Fabric. Widely used in industries ranging from agriculture and construction to logistics and consumer goods, this fabric has proven to be a reliable solution for heavy-duty packaging and protective covering needs.

But what exactly is HDPE woven fabric, and why has it become such an integral part of industrial and commercial applications? Let’s dive deep into its properties, benefits, and uses.

For companies aiming to strike the right balance between performance and sustainability, HDPE woven fabric is undoubtedly the packaging material of choice.

-

Types of HDPE Woven Fabric

-

Laminated vs. Unlaminated

-

UV Stabilized Fabric

-

Color Options (white, transparent, colored)

-

Food-Grade vs. Industrial Grade

-

-

Different GSM (Grams per Square Meter) Options

-

Lightweight fabric (50–70 GSM)

-

Medium-duty (80–120 GSM)

-

Heavy-duty (130+ GSM)

-

How to select the right GSM for your application

-

-

Printing & Customization

-

Flexographic and rotogravure printing options

-

Branding benefits with printed fabrics

-

Adding logos, product details, and barcodes

-

-

Environmental Impact & Recycling

-

How HDPE woven fabric contributes to reducing plastic waste

-

Recycling process of HDPE woven fabric

-

Comparison with biodegradable packaging

-

-

Export & Compliance Certifications

-

ISO, BIS, and food safety certifications

-

Why international buyers prefer certified HDPE woven fabric

-

-

Industries Using HDPE Woven Fabric

-

Agriculture & Farming

-

Retail & E-commerce Packaging

-

Pharma & Chemicals

-

Infrastructure & Construction

-

-

Case Study / Example

-

Example: How farmers use HDPE woven fabric to cover harvested crops

-

Example: How exporters of rice or sugar benefit from HDPE woven sacks

-

-

Future Innovations

-

Breathable HDPE woven fabrics

-

Anti-static woven bags for electronics

-

Biodegradable additives in HDPE

-

What is HDPE Woven Fabric?

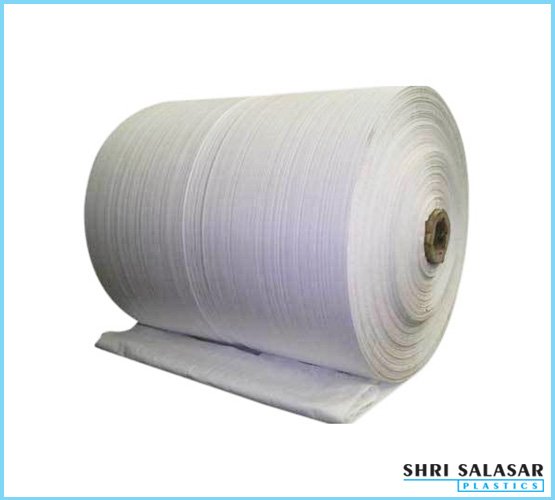

HDPE Woven Fabric is made from High-Density Polyethylene (HDPE) granules that are extruded into tapes or yarns, which are then woven into a strong, flexible fabric. This fabric is lightweight yet durable, making it ideal for applications where strength and resistance to wear and tear are essential.

Unlike ordinary fabrics, HDPE woven fabric is not used for clothing it’s primarily used in packaging, covering, and protective solutions because of its tensile strength, chemical resistance, and weatherproof properties.

HDPE stands for High-Density Polyethylene, a thermoplastic polymer derived from petroleum. HDPE woven fabric is made by extruding HDPE granules into flat tapes, which are then woven on looms to form a strong, flexible, and lightweight fabric.

This fabric is commonly used in:

-

Packaging bags (HDPE woven sacks)

-

Tarpaulins and coverings

-

Industrial liners and sheets

-

Container bags and bulk packaging solutions

Its unique combination of tensile strength, weather resistance, and cost-effectiveness makes it the first choice for industries that require secure, long-lasting packaging.

Key Features of HDPE Woven Fabric

-

High Tensile Strength

-

Can carry heavy loads without tearing.

-

Suitable for bulk packaging like grains, cement, and fertilizers.

-

-

Lightweight Yet Durable

-

Easy to transport and handle.

-

Strong enough to withstand tough conditions.

-

-

Moisture and Weather Resistance

-

Protects against water, dust, and UV rays.

-

Ensures safe storage of goods outdoors.

-

-

Chemical Resistance

-

Does not react with most chemicals.

-

Ideal for packaging fertilizers, salts, and industrial powders.

-

-

Cost-Effective

-

Affordable compared to alternatives like jute or metal containers.

-

Offers long-term durability at low cost.

-

-

Eco-Friendly and Recyclable

-

100% reusable and recyclable.

-

Supports sustainable packaging practices.

-

Manufacturing Process of HDPE Woven Fabric

-

Extrusion: HDPE granules are melted and extruded into flat tapes.

-

Weaving: These tapes are woven on circular or flat looms to form the fabric.

-

Lamination (Optional): A thin layer of LDPE/PP film can be laminated for added moisture resistance.

-

Finishing: The fabric is cut, printed, and stitched into bags or rolls, depending on its final application.

Applications of HDPE Woven Fabric

1. Packaging Industry

-

Used for HDPE woven sacks and bags to pack rice, wheat, flour, sugar, fertilizer, and cement.

-

Provides excellent strength and protection during transport.

2. Agriculture Sector

-

Covers for crops, soil, and greenhouses.

-

Protects harvested crops from rain and dust.

3. Construction Industry

-

Used as tarpaulins for scaffolding and site covers.

-

Protects cement and raw materials from moisture.

4. Transport & Logistics

-

Container liners, box bags, and bale wraps.

-

Ensures goods are safe during long-distance shipping.

5. Household & Retail

-

Reusable shopping bags and storage bags.

-

Eco-friendly replacement for single-use plastics.

6. Specialized Applications

-

Geotextiles for soil stabilization.

-

Fumigation covers and protective industrial sheets.

Advantages of Using HDPE Woven Fabric

-

Strength and Reliability – Can carry heavy weights without breaking.

-

Moisture Resistance – Protects against rain and damp conditions.

-

Reusability – Can be reused multiple times, reducing packaging costs.

-

Customizable – Available in different sizes, GSM (grams per square meter), and colors.

-

Branding Opportunities – Printable surfaces allow company logos and product information.

-

Eco-Friendly – Recyclable material contributes to sustainability.

HDPE Woven Fabric vs Jute Fabric

| Feature | HDPE Woven Fabric | Jute Fabric |

|---|---|---|

| Strength | Higher tensile strength | Moderate strength |

| Moisture Resistance | Excellent with lamination | Poor, absorbs water |

| Cost | More cost-effective | Relatively expensive |

| Reusability | Highly reusable and recyclable | Biodegradable but less durable |

| Applications | Industrial packaging, tarpaulins | Limited to eco-bags and handicrafts |

Clearly, HDPE woven fabric outperforms jute in industrial applications, while jute remains popular for eco-fashion and small-scale packaging.

Global Market and Demand

The demand for HDPE woven fabric is growing at a significant rate due to its versatility and affordability. According to industry reports, the global woven fabric market is expected to grow at a CAGR of 5–6% in the coming years.

Why Businesses Prefer HDPE Woven Fabric

-

Durability for Bulk Packaging – Ensures safe transport of goods.

-

Cost Savings – Reduces wastage and packaging costs.

-

Compliance with Global Standards – Meets requirements for food-grade and export packaging.

-

Sustainability – Supports eco-friendly practices by being recyclable.

Future of HDPE Woven Fabric

With increasing bans on single-use plastics, the demand for reusable and recyclable packaging solutions is at an all-time high. HDPE woven fabric is expected to play a major role in replacing non-biodegradable packaging materials.

Innovations such as UV-stabilized fabrics, breathable laminations, and anti-static coatings are expanding the scope of HDPE woven fabric into newer applications like geotextiles and e-commerce packaging.

Conclusion

HDPE Woven Fabric is more than just a packaging material—it is a versatile, durable, and eco-friendly solution trusted by industries worldwide. From protecting agricultural produce to securing construction materials and facilitating international trade, it has become the backbone of modern packaging.

Its strength, cost-effectiveness, and recyclability make it an indispensable choice for businesses seeking reliability and sustainability. As industries move towards greener practices, HDPE woven fabric is set to play an even more significant role in the future of industrial packaging. Read More