Pumps are essential in modern industries, households, and agriculture, ensuring a steady flow of liquids where natural pressure is not enough. However, when the source is deep underground or located far from the pump, conventional pumps fail to deliver. This is where the high suction pump proves its worth.

Known for its ability to handle challenging suction conditions, a high suction water pump provides unmatched efficiency in lifting fluids from depths. In this article, we will discuss the working principle, features, advantages, and applications of high suction pumps, along with tips for selection and maintenance.

What is a High Suction Pump?

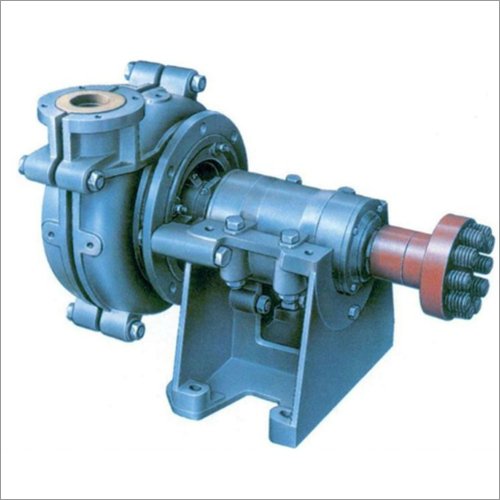

A high suction pump is a pumping device designed to lift water or other fluids from a source located much lower than the pump’s installation point. It is engineered to handle higher suction lifts compared to standard pumps.

These pumps are widely used in:

-

Deep borewell water extraction

-

Irrigation in agricultural fields

-

Industrial plants handling chemicals and effluents

-

Dewatering in mining and construction projects

In simple terms, whenever water or fluid needs to be drawn from a depth beyond the capacity of normal pumps, a high suction water pump is the preferred choice.

Working Principle of High Suction Pump

The working of a high suction pump relies on fluid mechanics and pressure difference. Here’s how it functions:

-

Vacuum Creation – The pump’s impeller or diaphragm creates a vacuum in the casing.

-

Atmospheric Push – Atmospheric pressure pushes the liquid into the suction line.

-

Energy Transfer – The impeller converts mechanical energy into kinetic and pressure energy.

-

Fluid Discharge – The liquid flows out through the delivery pipe under pressure.

This simple yet powerful principle allows the pump to lift fluids from significant depths while maintaining consistent output.

Features of High Suction Pumps

High suction pumps are designed with special features that set them apart:

-

Deep Suction Lift – Can extract fluids from depths that exceed ordinary pump capacity.

-

Robust Construction – Built with durable materials like stainless steel, cast iron, or alloys.

-

Corrosion Resistance – Suitable for handling water, wastewater, and chemicals.

-

Energy Efficient – Optimized for high performance with minimal energy loss.

-

Wide Range – Available in centrifugal, submersible, diaphragm, and self-priming designs.

-

Versatile Use – Works for domestic, agricultural, and industrial needs.

Types of High Suction Pumps

High suction pumps are classified based on their design and application:

1. Centrifugal High Suction Pump

-

Uses centrifugal force for pumping.

-

Best for clean water supply and irrigation.

-

Low maintenance and cost-effective.

2. Submersible High Suction Pump

-

Operates underwater inside the source.

-

No priming required.

-

Perfect for borewells, drainage, and sewage.

3. Diaphragm High Suction Pump

-

Uses diaphragm action for suction and discharge.

-

Can pump viscous, abrasive, and chemical fluids.

-

Ideal for industries like pharmaceuticals and chemicals.

4. Self-Priming High Suction Pump

-

Starts without manual priming.

-

Reduces downtime and increases reliability.

-

Often used in fire-fighting systems.

5. Vacuum-Assisted High Suction Pump

-

Employs vacuum technology to enhance suction power.

-

Common in dewatering operations for construction and mining.

Advantages of High Suction Pumps

Using a high suction pump offers several advantages:

-

Reliable Performance – Consistent flow even under challenging suction conditions.

-

Durability – Long service life with sturdy build.

-

Handles Multiple Fluids – From clean water to sludge and chemicals.

-

Cost-Efficient – Reduces water extraction costs in the long run.

-

Versatility – Applicable in agriculture, industry, and municipal supply.

-

Ease of Use – Advanced models require minimal intervention.

Applications of High Suction Pumps

The versatility of high suction pumps makes them indispensable across industries:

Agriculture

-

Lifting water from borewells for irrigation.

-

Supplying water to farms in areas with low water tables.

Domestic and Municipal Use

-

Extracting groundwater for residential water supply.

-

Pumping water to overhead tanks in municipal systems.

Industry

-

Transferring oils, fuels, and industrial fluids.

-

Managing wastewater in refineries and chemical plants.

Construction and Mining

-

Removing floodwater from construction sites.

-

Dewatering mining pits and tunnels.

Fire-Fighting Systems

-

Providing rapid and powerful suction in emergencies.

Marine

-

Handling bilge water and seawater.

-

Supporting onboard pumping operations.

How to Choose the Right High Suction Pump

When selecting a high suction pump, evaluate the following factors:

-

Depth of Source – Ensure pump capacity matches suction lift needs.

-

Flow Rate – Choose based on daily or hourly demand.

-

Fluid Type – Water, slurry, or chemicals require different pump materials.

-

Power Source – Select from electric, diesel, or solar-powered models.

-

Pump Material – Opt for stainless steel or corrosion-resistant alloys for durability.

-

Maintenance Requirements – Easy-to-maintain models reduce downtime.

Maintenance Tips for High Suction Pumps

To ensure efficiency and a long service life:

-

Inspect the pump regularly for leaks and wear.

-

Keep filters and suction pipes clean.

-

Lubricate moving parts at recommended intervals.

-

Monitor motor health to avoid overheating.

-

Replace seals, bearings, and impellers as needed.

Modern Innovations in High Suction Pumps

Technology has improved high suction pumps with advanced features:

-

IoT-Enabled Monitoring – Remote tracking of pump performance.

-

Variable Frequency Drives (VFDs) – For energy-efficient operation.

-

Advanced Materials – Corrosion-proof alloys for handling aggressive fluids.

-

Noise-Reduction Technology – Quiet functioning for industrial and residential use.

Why High Suction Pumps Are Indispensable

High suction pumps have become indispensable because they:

-

Ensure water supply in areas with low water tables.

-

Support industries in handling challenging fluids.

-

Enable construction and mining operations with reliable dewatering.

-

Provide quick response in fire-fighting and emergency applications.

Applications of High Suction Pumps

The versatility of high suction pumps makes them indispensable across industries:

Agriculture

-

Lifting water from borewells for irrigation.

-

Supplying water to farms in areas with low water tables.

Domestic and Municipal Use

-

Extracting groundwater for residential water supply.

-

Pumping water to overhead tanks in municipal systems.

Industry

-

Transferring oils, fuels, and industrial fluids.

-

Managing wastewater in refineries and chemical plants.

Construction and Mining

-

Removing floodwater from construction sites.

-

Dewatering mining pits and tunnels.

Fire-Fighting Systems

-

Providing rapid and powerful suction in emergencies.

Marine

-

Handling bilge water and seawater.

-

Supporting onboard pumping operations.

Conclusion

A high suction water pump is more than just a tool for fluid transfer—it is a dependable solution for deep water lifting and industrial applications. Its strength lies in its ability to maintain performance in demanding environments, from farms to factories and from municipal water systems to marine vessels.

By selecting the right type, ensuring proper maintenance, and leveraging new innovations, users can rely on high suction pumps for efficiency, durability, and cost-effectiveness.