Extrusion manufacturing has been a backbone of industries such as plastics, packaging, food, pharmaceuticals, and construction for decades. Traditionally, extrusion involved a mix of manual monitoring, operator expertise, and mechanical processes. But as industries face increasing pressure to improve efficiency, reduce costs, and deliver consistent quality, automation is reshaping how extrusion plants operate.

From advanced sensors to AI-driven predictive systems, automation technologies are changing every stage of the extrusion process. This blog explores how automation is transforming extrusion manufacturing, the benefits it brings, and what the future may hold.

The Role of Extrusion in Modern Manufacturing

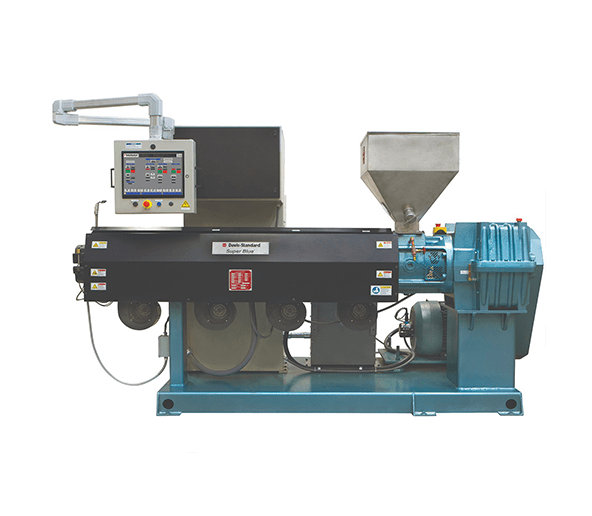

Before diving into automation, it’s important to understand why extrusion is so critical. At its core, extrusion is a process where raw material is pushed through a die to create a continuous profile. This can include plastic pipes, food products like pasta, aluminum profiles, or pharmaceutical pellets.

The extruder machine is the heart of this process, applying heat, pressure, and mechanical force to shape raw material into consistent products. Because extrusion must maintain tight tolerances and handle complex formulations, it is highly sensitive to operational efficiency, making automation an ideal solution.

1. Real-Time Monitoring and Control

Automation introduces real-time monitoring across the extrusion line. Sensors track variables such as:

-

Barrel temperature

-

Screw speed

-

Pressure at various stages

-

Material feed rates

-

Product dimensions

Instead of relying on manual checks, automated control systems continuously adjust operating conditions. For example, if the temperature drifts outside the desired range, the system can correct it instantly, preventing waste and maintaining product consistency.

This not only improves accuracy but also reduces the risk of human error, which is common in manual setups.

2. Enhanced Product Quality

Quality is the cornerstone of extrusion. Automated systems ensure that product dimensions, surface finish, and strength remain consistent across batches. With inline sensors and laser measurement systems, product quality is tracked without interrupting the process.

Automation also allows for tighter control of formulations. For industries like pharmaceuticals and food, even small deviations can cause compliance issues or product recalls. Automated extrusion minimizes these risks by standardizing every parameter.

3. Improved Efficiency and Throughput

Automation enables extrusion lines to run continuously with minimal stoppages. Features like automated material feeding, self-adjusting die heads, and advanced cooling systems ensure uninterrupted operation.

Key efficiency gains include:

-

Faster startup times due to pre-programmed settings.

-

Reduced downtime through predictive maintenance.

-

Energy savings by optimizing temperature and motor usage.

As a result, manufacturers can achieve higher throughput without sacrificing quality, directly boosting profitability.

4. Predictive Maintenance with AI and IoT

One of the biggest challenges in extrusion manufacturing is unexpected breakdowns. Traditionally, maintenance followed fixed schedules or was reactive when problems occurred. Both approaches can be costly.

Automation, combined with IoT and AI, introduces predictive maintenance. Sensors on motors, screws, and bearings collect data on vibration, load, and temperature. AI algorithms analyze this data to predict potential failures before they occur.

This means maintenance can be scheduled during planned downtime, avoiding sudden stoppages and costly repairs. Predictive maintenance not only extends equipment lifespan but also reduces overall maintenance costs.

5. Data-Driven Decision Making

Modern extrusion systems generate vast amounts of data. Automated systems collect and organize this data into dashboards and reports, giving managers insights into:

-

Production efficiency

-

Material usage

-

Energy consumption

-

Product reject rates

With this information, manufacturers can make informed decisions to optimize operations, reduce waste, and improve profitability. Over time, these insights can also guide process improvements and strategic investments.

6. Flexibility and Customization

Market demand is shifting rapidly, with customers expecting more customized products in smaller batches. Automation gives extrusion plants the flexibility to switch between product lines quickly.

Features such as recipe management allow operators to save multiple product configurations. Changing from one product to another is as simple as loading the right recipe, reducing setup times and ensuring consistent results.

This flexibility is particularly valuable in industries like packaging and food, where consumer trends change quickly.

7. Workforce Transformation

While automation reduces the need for manual tasks, it does not eliminate the need for skilled workers. Instead, it transforms their roles.

Operators now focus on:

-

Supervising automated systems.

-

Interpreting data and optimizing performance.

-

Handling maintenance and troubleshooting.

This shift requires training and upskilling, but it also creates safer, more rewarding jobs by reducing repetitive and physically demanding work.

8. Sustainability and Energy Efficiency

Sustainability is a growing priority for industries worldwide. Automation helps extrusion manufacturers reduce their environmental impact in several ways:

-

Energy optimization lowers power consumption.

-

Reduced material waste thanks to tighter process control.

-

Improved recycling as automated systems handle regrind and recycled materials more effectively.

For companies seeking to meet sustainability goals or achieve certifications, automation is a key enabler.

9. Integration with Industry 4.0

Automation in extrusion is part of a broader trend—Industry 4.0, which combines smart factories, connected devices, and digital transformation.

Extrusion lines can now integrate with enterprise systems for:

-

Remote monitoring and control.

-

Automated supply chain management.

-

Real-time production planning.

This level of integration turns extrusion from a standalone process into a fully connected part of the digital manufacturing ecosystem.

10. Competitive Advantage Through Automation

In industries where margins are tight and customer demands are high, automation provides a clear competitive edge. By delivering consistent quality, faster turnaround times, and greater flexibility, automated extrusion lines help businesses differentiate themselves in the marketplace. Companies that invest in automation can respond more quickly to customer needs, reduce operational costs, and build a reputation for reliability—all of which translate into long-term growth.

The Future of Automated Extrusion

As automation technologies advance, extrusion manufacturing will continue to evolve. We can expect:

-

Greater use of AI for autonomous decision-making.

-

Increased adoption of robotics for handling and packaging.

-

Enhanced simulation and digital twins for process optimization.

-

More sustainable designs focused on renewable energy and recycled materials.

Companies that embrace automation today will be well-positioned to thrive in this future landscape.

Conclusion

Automation is no longer optional in extrusion manufacturing—it’s essential. From real-time monitoring and predictive maintenance to improved efficiency and sustainability, automation delivers measurable benefits across the production line.

By leveraging advanced technologies, manufacturers can ensure consistent quality, reduce costs, and stay competitive in an increasingly demanding market. The future of extrusion is smart, connected, and highly automated—and businesses that adapt early will reap the rewards.