When it comes to building or upgrading an industrial facility, one of the most overlooked yet crucial decisions is flooring. Industrial flooring isn’t just about having a surface to walk or drive on—it’s about creating a foundation that supports productivity, safety, hygiene, and cost efficiency. The right flooring system can improve operational performance, minimize downtime, and ensure compliance with industry standards.

In this article, we’ll explore the key benefits of industrial flooring, highlighting why it’s an essential investment for factories, warehouses, laboratories, food processing plants, logistics hubs, and many other facilities.

1. Durability and Long Lifespan

One of the primary reasons industries invest in specialized flooring is durability. Industrial environments often face extreme conditions, such as:

-

Heavy machinery and forklift traffic

-

Chemical spills and exposure to solvents

-

Abrasive materials and dropped equipment

-

Continuous wear from high foot traffic

Standard flooring materials like untreated concrete or basic tiles can quickly crack, chip, or erode under these conditions. Industrial flooring systems—such as epoxy, polyurethane, or polished concrete—are engineered to withstand intense stress without degrading prematurely.

The benefit here is longevity. A properly installed industrial floor can last decades with minimal maintenance, reducing the need for frequent replacements and keeping operations running smoothly.

2. Safety Enhancement

Safety is a top priority in any industrial setting. Floors play a direct role in minimizing workplace accidents such as slips, trips, and falls. Many industrial flooring solutions include anti-slip surfaces, textured finishes, or coatings that maintain traction even in wet or oily conditions.

Some flooring types also have fire-resistant or spark-resistant properties, which are critical in environments where flammable substances are present. Additionally, certain floors can be color-coded or marked to highlight safety zones, pedestrian walkways, and hazardous areas, reinforcing visual communication in the workplace.

In short, industrial flooring helps reduce accidents, protect employees, and ensure compliance with occupational health and safety regulations.

3. Chemical and Stain Resistance

In industries like pharmaceuticals, food processing, automotive, and manufacturing, chemical spills are common. Traditional flooring can absorb liquids, leading to staining, deterioration, or even contamination.

Industrial flooring systems—especially epoxy and polyurethane coatings—are formulated to be impervious to chemicals, oils, acids, and cleaning agents. This not only protects the structural integrity of the floor but also makes cleaning up spills easier and safer.

The resistance to staining and chemical damage ensures the facility remains professional-looking, hygienic, and compliant with strict cleanliness standards.

4. Hygiene and Easy Maintenance

Hygiene is critical in industries such as healthcare, food and beverage production, and pharmaceuticals. Floors in these environments must prevent the growth of bacteria, mold, and fungi. Industrial flooring solutions offer seamless finishes without grout lines, cracks, or joints where dirt and microbes can accumulate.

Smooth, non-porous surfaces are much easier to clean and sanitize. Many industrial flooring systems are compatible with high-pressure washing, steam cleaning, and strong disinfectants, allowing facilities to maintain strict hygiene protocols effortlessly.

This results in reduced risk of contamination, improved product safety, and compliance with health regulations like FDA or HACCP standards.

5. Aesthetic and Professional Appeal

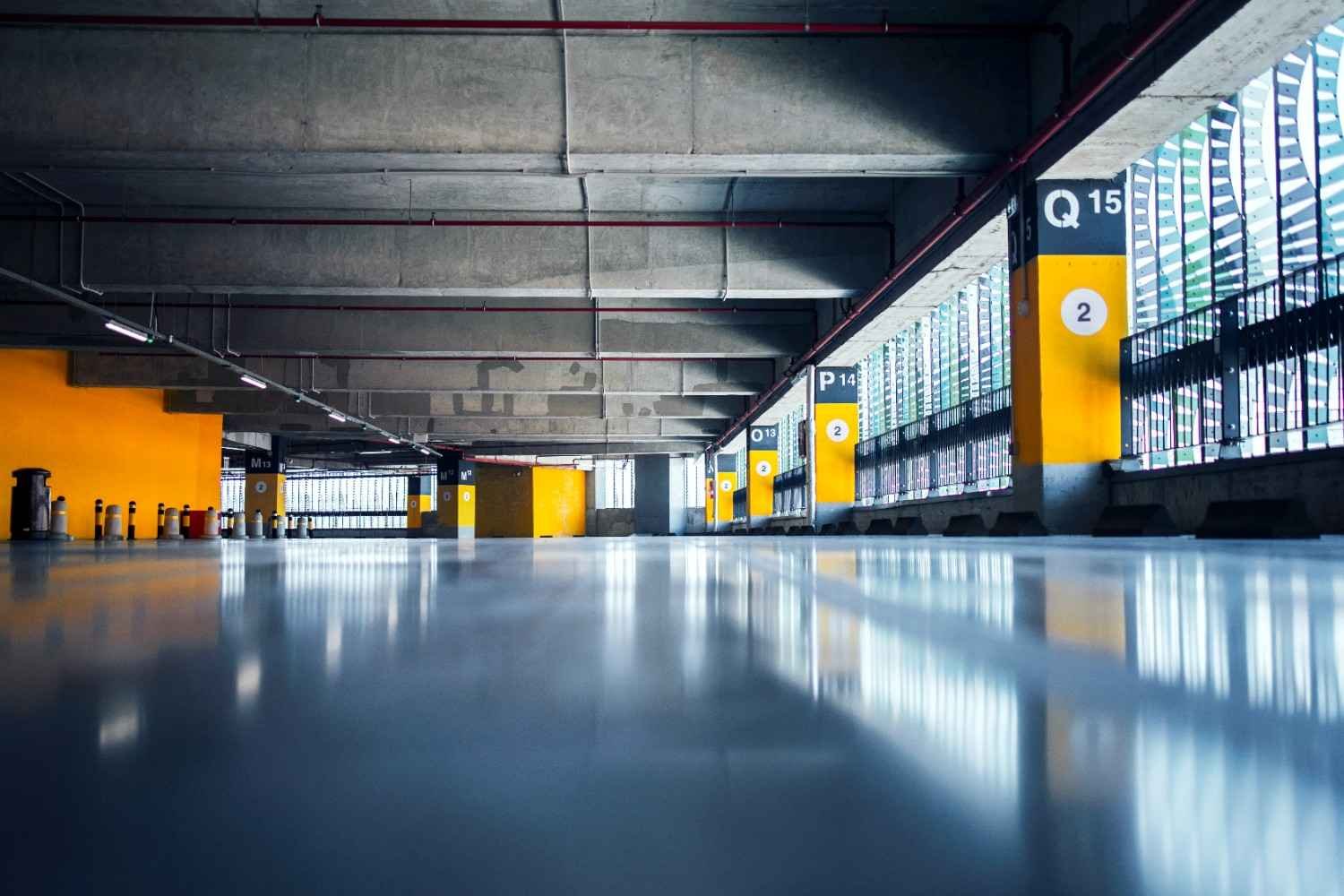

Although function is the primary goal, aesthetics should not be ignored. A well-installed industrial floor can dramatically improve the look of a facility. Options like epoxy and polished concrete can be customized with colors, patterns, high-gloss finishes, or matte textures.

For customer-facing or client-tour environments, an attractive floor enhances brand image and reflects professionalism. Bright, clean floors also improve employee morale, creating a more pleasant and motivating workspace.

Additionally, light-reflective flooring helps enhance natural and artificial lighting, making facilities brighter and reducing electricity costs.

6. Load-Bearing Capacity

Industrial floors must endure extreme weight loads from heavy machinery, stacked goods, and constant traffic from forklifts or pallet jacks. Specialized industrial flooring systems are designed with high compressive strength and impact resistance, ensuring they don’t crack under pressure.

This load-bearing capacity allows facilities to use large-scale equipment and store heavy products without worrying about floor damage, which in turn prevents costly repairs and downtime.

7. Cost Efficiency Over Time

At first glance, industrial flooring installation may seem like a significant investment. However, the long-term savings far outweigh the upfront costs. Consider the following:

-

Reduced maintenance costs – Minimal repairs and easy cleaning

-

Fewer replacements – Long-lasting flooring reduces capital expenditure

-

Improved energy efficiency – Light-reflective surfaces lower lighting costs

-

Decreased downtime – Durable flooring prevents operational disruptions

In the long run, industrial flooring proves to be one of the most cost-efficient infrastructure investments, offering a strong return on investment for businesses.

8. Customization and Flexibility

No two industries are alike, and neither are their flooring needs. Industrial flooring systems can be tailored to meet specific requirements, such as:

-

Anti-static coatings for electronics and data centers

-

Thermal resistance for bakeries, breweries, and cold storage facilities

-

Shock-absorbing surfaces for sports and fitness centers

-

High-gloss finishes for showrooms and cleanrooms

This flexibility ensures that businesses can install flooring that directly supports their operational demands, maximizing efficiency and safety.

9. Environmental and Sustainability Benefits

Modern industrial flooring solutions are increasingly designed with eco-friendly materials and low-VOC coatings, reducing harmful emissions during installation and use. Polished concrete, for instance, makes use of existing concrete slabs, eliminating the need for new raw materials.

Some systems also contribute to energy efficiency by enhancing natural light reflectivity. Choosing sustainable flooring not only benefits the environment but also helps businesses meet corporate sustainability goals and earn certifications such as LEED (Leadership in Energy and Environmental Design).

10. Compliance with Industry Standards

Many industries must adhere to strict regulations regarding workplace safety, hygiene, and environmental standards. Industrial flooring plays a crucial role in ensuring compliance. For example:

-

Food industry: HACCP-compliant surfaces that prevent contamination

-

Pharmaceuticals: GMP standards requiring clean, sterile flooring

-

Manufacturing: OSHA standards for slip resistance and safety markings

By investing in the right flooring, businesses can avoid fines, maintain certifications, and operate confidently within regulatory frameworks.

11. Rapid Installation and Minimal Downtime

Modern flooring technologies allow for quick installation with fast-curing materials that minimize downtime. Some systems can even be applied over existing floors, reducing the need for demolition and disposal.

This is particularly valuable for 24/7 operations like warehouses, logistics hubs, and manufacturing plants, where downtime can result in significant financial losses.

Conclusion

Industrial flooring is far more than just a surface to walk on—it’s the foundation of a safe, efficient, and productive facility. The benefits are extensive: from durability, safety, and hygiene to aesthetics, cost savings, and regulatory compliance. By investing in the right industrial flooring system, businesses can create an environment that supports long-term growth, protects employees, and ensures smooth daily operations.

Whether it’s epoxy, polyurethane, or polished concrete, the best industrial flooring is the one tailored to the facility’s unique needs. Ultimately, the right choice transforms the floor from a passive surface into a strategic asset for success.