In the realm of instrumentation and fluid control systems, male connector tube fittings play a pivotal role in ensuring secure, leak-proof, and pressure-resistant connections. These fittings are integral to industries such as oil & gas, petrochemical, power generation, shipbuilding, and semiconductor manufacturing, where reliability and precision are non-negotiable.

In this technical deep dive, we’ll explore the design, materials, working principles, standards, and applications of male connector tube fittings and why they’re essential to fluid system performance.

What Are Male Connector Tube Fittings?

Male connector tube fittings are components used to connect a tube to a female-threaded port. The male connector features a straight or tapered male thread on one end and a tube connection (compression/swagelok-type or flare-type) on the other.

They serve as a transitional element between piping and instrumentation systems converting seamless tubes into standard threaded connections.

Design and Components

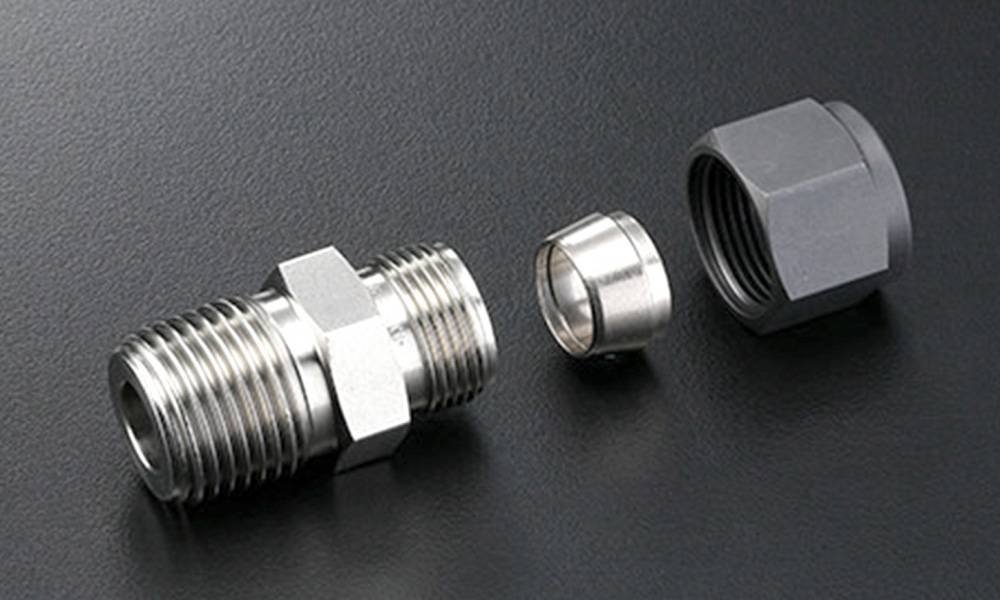

A typical male connector tube fitting includes:

-

Body: Houses the male thread and the port for tube insertion.

-

Ferrules (front and back): Provide the sealing and gripping mechanism (in compression-type fittings).

-

Nut: Tightens the ferrules against the tube and fitting body.

For single-ferrule systems, only one ferrule is used. In double-ferrule systems (e.g., Swagelok-type), front and back ferrules distribute stress and enhance grip/seal performance.

Materials and Metallurgy

The material selection for male connector tube fittings is dictated by application parameters — temperature, pressure, corrosion resistance, and media compatibility. Common materials include:

-

Stainless Steel 316/316L: Excellent corrosion resistance in aggressive environments.

-

Brass: Economical, suitable for low-pressure water or gas systems.

-

Monel 400 / Inconel 625 / Hastelloy C276: For highly corrosive or marine/offshore environments.

-

Carbon Steel: Preferred in hydraulic systems with compatible fluid media.

Material Certification (EN 10204 3.1 / NACE MR0175) is often mandatory in process-critical industries.

Thread Standards & Dimensions

The male thread end of the connector complies with various global standards:

-

NPT (National Pipe Tapered) – ASME B1.20.1

-

BSPT/BSPP (British Standard Pipe Tapered/Parallel) – ISO 7-1 / ISO 228

-

UN/UNF (Unified National Fine) – SAE J514

-

Metric Threads – ISO 261 / DIN 3852

Each standard defines thread pitch, taper angle, sealing method (mechanical vs thread-sealant), and pressure ratings.

Performance Parameters

| Parameter | Range / Value |

|---|---|

| Operating Pressure | Up to 6,000 psi (414 bar) |

| Operating Temperature | -250°C to +650°C (Depending on material) |

| Vibration Resistance | High (especially in double-ferrule design) |

| Sealing Method | Mechanical grip + metal-to-metal seal |

| Tube OD Compatibility | 1/8” to 2” (3mm to 50mm) |

Helium leak test, pressure cycling, and vibration fatigue tests are often performed to validate connector performance.

Industrial Applications of Male Connector Tube Fittings

-

Oil & Gas Refineries

-

Instrumentation lines for pressure, temperature, and flow control

-

Connection of impulse lines to transmitters and manifolds

-

-

Chemical & Petrochemical Plants

-

Aggressive fluids handling under high pressure and temperature

-

Corrosion-resistant tubing systems

-

-

Power Generation (Thermal, Nuclear, Renewable)

-

Hydraulic and pneumatic control circuits

-

Steam and water sampling systems

-

-

Pharmaceutical & Food Processing Units

-

Clean-in-place (CIP) systems

-

Sanitary-grade instrumentation

-

-

Marine & Offshore

-

Saltwater-resistant fittings using Monel or Duplex

-

Fuel and ballast system instrumentation

-

Installation Guidelines

-

Always use tube inserts when working with soft or plastic tubing.

-

Use a proper tube cutter to ensure square, burr-free ends.

-

For compression fittings, tighten the nut 1 1/4 turns past hand-tight (for initial installation).

-

Never reuse ferrules; always replace them with new ones.

-

Torque wrenches are recommended to ensure correct sealing force.

Certifications & Compliance

Top manufacturers ensure male connector tube fittings comply with:

-

ASTM A276 / A479 / A182 (Material specs)

-

NACE MR0103 / MR0175 (Corrosion resistance for sour service)

-

ISO 8434 / DIN 2353 / SAE J514 (Fitting standards)

-

PED / CE Marking / RoHS / REACH (European compliance)

Male Connector Tube Fitting Configurations

| Configuration | Application |

|---|---|

| Straight Male Connector | General purpose inline connections |

| 45° Male Elbow | Angled systems requiring direction change |

| 90° Male Elbow | Right-angle connections in compact spaces |

| Bulkhead Male Connector | Through-wall panel installations |

| Reducing Male Connector | Tube-to-thread transitions with size difference |

Why Engineers Prefer High-Quality Male Connectors

-

Leak-free performance under pulsating and dynamic loads

-

Compact footprint for space-constrained designs

-

Ease of assembly and disassembly during maintenance

-

High-pressure and high-temperature resistance

-

Long service life with low failure rate

Conclusion

Male connector tube fittings are not just accessories they’re mission-critical components engineered for precision and durability. Whether it’s a high-pressure hydraulic line in an offshore platform or a gas chromatograph in a pharmaceutical lab, these fittings ensure uncompromised reliability and flow integrity.

Choosing the right material, thread type, and fitting design directly influences the safety, efficiency, and longevity of your fluid system.

If you’re looking to source high-quality male connector tube fittings that comply with global standards and perform under the toughest conditions — make sure to partner with a trusted manufacturer with proven metallurgical expertise and application experience.