In industrial mixing processes, achieving uniformity is essential for ensuring product quality, consistency, and efficiency. Whether you are blending powders, granules, or semi-solid materials, the design of the mixing equipment plays a critical role in the final outcome. Among the many types of industrial blenders, the ribbon mixer is one of the most widely used because of its simple structure, high efficiency, and ability to handle a wide range of materials.

Table of Contents

ToggleTwo of the most important design factors that determine the performance of a ribbon mixer are the ribbon design and pitch angle. Understanding how these factors work together can help manufacturers achieve optimal mixing uniformity and avoid issues like dead zones, uneven blending, or overmixing.

Understanding the Basics of Ribbon Mixing

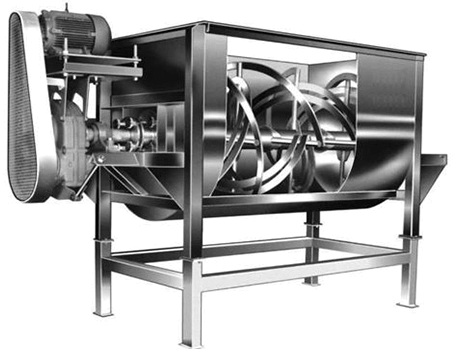

A ribbon mixer consists of a horizontal U-shaped trough, a central shaft, and a set of helical ribbons (also called blades) mounted on the shaft. These ribbons rotate to move material both radially and axially within the trough. Typically, the outer ribbon moves materials in one direction (usually toward the discharge end), while the inner ribbon moves them in the opposite direction.

This counter-current motion ensures continuous circulation and helps blend materials thoroughly in a relatively short time. However, how effectively the mixer performs depends heavily on how the ribbons are designed and at what angle they are pitched.

What Is Ribbon Design?

Ribbon design refers to the shape, width, thickness, and arrangement of the ribbons inside the mixer. These factors determine how materials move during mixing and how efficiently energy is transferred to the particles.

There are generally two types of ribbon configurations:

-

Single Helical Ribbon:

This design features one continuous helical ribbon. It’s simpler and suitable for less demanding mixing tasks where high uniformity isn’t critical. -

Double Helical Ribbon:

This configuration has two counter-pitched ribbons—an inner and an outer one. The outer ribbon moves materials in one direction, while the inner ribbon pushes them in the opposite direction. This creates a more dynamic flow pattern, enhancing mixing uniformity and reducing mixing time.

The width and thickness of the ribbons also matter. Wider ribbons move more material but require more power, while thinner ribbons generate gentle movement, which is ideal for fragile or light materials. The optimal design depends on the characteristics of the materials being mixed—such as bulk density, particle size, and flow behavior.

What Is Pitch Angle?

The pitch angle of a ribbon refers to the angle of inclination of the ribbon blades relative to the axis of the shaft. This angle controls how materials move through the mixer—both along its length and across its cross-section.

A larger pitch angle increases axial movement (material traveling from one end of the mixer to the other), while a smaller pitch angle promotes more radial or circular mixing.

In simple terms:

-

Large pitch angle (steeper blades): Faster movement, shorter mixing time, but possibly less thorough blending if not optimized.

-

Small pitch angle (flatter blades): Slower material movement, longer mixing time, but potentially better uniformity.

Getting this balance right is key to achieving optimal mixing performance.

How Ribbon Design and Pitch Angle Work Together

The ribbon design and pitch angle must work in harmony to ensure consistent and uniform mixing. Here’s how they interact:

-

Material Flow Pattern:

The outer and inner ribbons move materials in opposite directions. The pitch angle defines the strength of this movement. If the angle is too high, materials may move too quickly along the mixer, leading to poor cross-mixing. If it’s too low, materials may circulate locally without proper axial distribution. -

Mixing Time:

Proper design reduces dead zones—areas in the mixer where materials remain stationary. With an optimal pitch and ribbon width, the materials constantly move and overlap, reducing the time needed to achieve homogeneity. -

Energy Efficiency:

Efficient design reduces power consumption. Overly aggressive ribbon geometry can demand excessive torque, while too gentle a design wastes time and energy in achieving uniformity. -

Shear Intensity:

Some products, such as fragile food ingredients or plastic pellets, can be damaged by high shear. The ribbon’s geometry and pitch angle control how much mechanical force the materials experience during mixing.

Design Considerations for Uniform Mixing

When designing or selecting a ribbon mixer, it’s essential to consider the following aspects:

1. Material Characteristics

Different materials behave differently under mechanical movement. Free-flowing powders need higher pitch angles for sufficient movement, while sticky or cohesive materials require lower angles to prevent clogging.

2. Filling Level

Ribbon mixers typically perform best when filled between 40% and 70% of their capacity. Too little material leads to poor contact between ribbons and particles, while overfilling restricts movement and reduces efficiency.

3. Speed of Rotation

The ribbon’s speed should complement its pitch angle. High speeds with steep pitches can lead to segregation, while low speeds with shallow pitches may result in under-mixing. A balance between the two ensures uniform results.

4. Clearance Between Ribbon and Trough

The gap between the ribbon blades and the trough wall affects how well material moves. Too large a gap leaves unmixed material at the edges; too small a gap increases friction and energy use. Precision manufacturing helps maintain optimal clearance.

Optimizing for Specific Applications

Different industries require specific design configurations:

-

Food and Beverage: Gentle mixing to preserve texture; ribbons often designed with moderate pitch angles.

-

Pharmaceuticals: High uniformity required; close tolerances and customized ribbon geometry are crucial.

-

Chemicals and Fertilizers: Heavier materials may require steeper angles and stronger ribbons for efficient axial movement.

-

Plastics and Polymers: Avoid overheating or shearing; moderate pitch with smooth, polished surfaces helps prevent buildup.

By understanding the nature of the material and the mixing goal—whether it’s coating, blending, or homogenizing—engineers can design ribbons and pitch angles tailored for optimal performance.

The Science Behind Uniform Mixing

Uniform mixing isn’t just about movement—it’s about how many times particles come into contact with each other during operation. Proper ribbon design ensures that all materials experience consistent motion, promoting efficient diffusion and distribution.

Studies and computational models show that double-helical ribbons with pitch angles between 30° and 45° generally provide a good balance between axial and radial flow for most dry powders. However, this range can vary depending on mixer size and material properties.

Conclusion

The ribbon mixer’s effectiveness lies in the thoughtful combination of ribbon design and pitch angle. Together, these factors determine how materials flow, mix, and achieve uniformity within the mixing chamber.

A well-designed ribbon mixer ensures faster blending, consistent product quality, and reduced operational costs. By understanding how ribbon geometry and pitch interact, manufacturers can optimize their equipment for specific applications—resulting in better performance, energy efficiency, and product consistency.

In short, achieving uniform mixing is not just about running the machine—it’s about engineering the right ribbon design and pitch angle to let the mixer do its job perfectly.