Prototype molding services have become an essential tool for modern businesses looking to reduce costs, accelerate product development, and improve product quality. These services allow companies to test and refine designs before moving into full-scale production. By taking advantage of prototype molding, businesses can save time, avoid costly errors, and increase overall efficiency. However, the key to achieving these benefits lies in understanding how to effectively use and optimize these services.

In this article, we’ll explore practical strategies and tips to help businesses maximize efficiency with prototype molding services. From proper design preparation to leveraging technology, supplier collaboration, cost management, and adopting industry best practices, these insights will guide you toward achieving greater productivity and success in your product development journey.

Start with a Well-Defined Design Plan

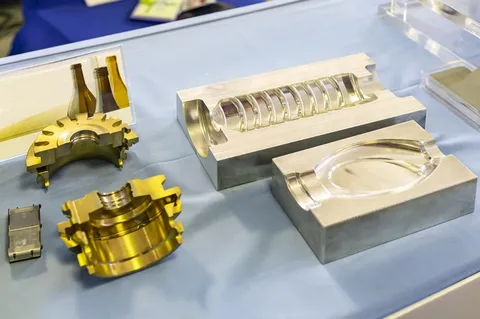

When working with prototype molding services, the first step to maximizing efficiency is to establish a clear and well-defined design plan. Companies often waste time and money when they enter the prototyping process without having a precise idea of their goals, features, and expectations. A thorough design plan ensures that the prototype reflects the actual product’s purpose and functionality, minimizing revisions later on. Using 3D modeling software can help visualize the design, simulate performance, and detect potential flaws before committing resources to mold creation.

Additionally, businesses should consider the manufacturability of their designs. A prototype may look impressive, but if it cannot be mass-produced efficiently, it becomes counterproductive. By collaborating with engineers and designers early in the process, companies can avoid common pitfalls such as unnecessary complexity or design features that increase costs without adding value. The more precise and realistic the design, the easier it becomes to create molds that deliver accurate and functional prototypes.

Choose the Right Materials for Your Prototype

Material selection plays a crucial role in maximizing efficiency when using prototype molding services. The choice of material affects not only the prototype’s performance but also its production speed, cost, and durability. For instance, thermoplastics are often favored due to their versatility, cost-effectiveness, and ease of molding. On the other hand, specialized materials such as silicone or elastomers may be necessary for products that require flexibility or heat resistance. Choosing the right material from the start reduces the risk of multiple iterations and wasted resources.

Another tip is to align material selection with the prototype’s intended purpose. If the prototype is only being used for visual presentation, a cheaper and less durable material might suffice. However, if the prototype will undergo functional testing, the chosen material should closely match the one intended for the final product. By balancing functionality with cost-effectiveness, businesses can ensure their prototypes serve their intended purpose without overspending or causing production delays.

Collaborate Closely with Prototype Molding Experts

Collaboration with skilled professionals is a powerful way to maximize efficiency in prototype molding services. While in-house teams may have the design vision, experienced molding experts can provide valuable insights into mold design, production feasibility, and optimization techniques. Early involvement of these experts helps to identify potential issues and streamline the prototyping process. Their knowledge can guide material choices, mold structures, and even help reduce cycle times in production.

Furthermore, maintaining consistent communication throughout the project is essential. Businesses that treat their prototype molding service providers as partners rather than just vendors often achieve better outcomes. Sharing feedback, discussing goals, and asking for expert recommendations fosters a cooperative environment that saves time and improves results. By working closely with prototype molding professionals, companies can reduce revisions, avoid delays, and create more effective prototypes that speed up the overall product development timeline.

Focus on Cost Efficiency Without Sacrificing Quality

Maximizing efficiency in prototype molding services isn’t just about speed—it’s also about managing costs effectively. One of the most common mistakes businesses make is focusing solely on cutting expenses, which can result in poor-quality prototypes. A balance must be struck between affordability and performance. To achieve this, businesses should prioritize smart cost-saving measures such as consolidating prototype runs, reusing molds where possible, and selecting cost-effective materials that still meet functional requirements.

Another approach to cost efficiency is adopting rapid prototyping methods when possible. Technologies such as 3D printing and CNC machining can supplement traditional molding techniques, providing affordable solutions for testing concepts before moving to full-scale molding. This hybrid approach reduces wasted resources and minimizes risks. By keeping cost efficiency in focus without compromising on quality, businesses can achieve better outcomes and ensure their prototype molding investments generate long-term value.

Leverage Technology and Continuous Improvement Practices

The final tip for maximizing efficiency with prototype molding services is to leverage technology and continuously improve processes. Advanced simulation software, automation tools, and digital manufacturing platforms are transforming the prototyping landscape. Using these technologies, businesses can predict how materials will behave, optimize mold designs, and speed up testing phases. This not only shortens the product development cycle but also improves accuracy, ensuring fewer revisions are required.

Continuous improvement is equally important. Companies should view prototype molding as an iterative learning process rather than a one-time task. By analyzing results, collecting feedback, and implementing improvements, businesses can refine their designs and processes over time. Regularly reviewing the performance of prototypes, tracking key performance indicators (KPIs), and incorporating lessons learned ensures that each new prototype is more efficient than the last. This mindset of ongoing innovation maximizes efficiency and keeps businesses competitive in fast-paced markets.

Conclusion

Prototype molding services are an invaluable resource for businesses aiming to reduce costs, improve quality, and accelerate product development. However, to maximize efficiency, organizations must take a strategic approach. By starting with a clear design plan, choosing the right materials, collaborating with experts, focusing on cost efficiency, and leveraging technology, companies can unlock the full potential of prototype molding.

These tips not only help reduce wasted time and resources but also enhance product outcomes, ultimately contributing to business success. In today’s competitive environment, efficiency is the key to staying ahead, and effective use of prototype molding services can give companies the edge they need to thrive.