When metal meets the sea, sloppy choices become expensive fast. Monel 400 Round Bars solve a lot of common headaches: they resist chloride attack, survive cavitation and erosion better than many alternatives, and hold up under mechanical stress. Here’s the thing: Monel isn’t a miracle; it’s a deliberate choice for parts where corrosion and load combine to create real risk. Choose it where failure costs time, money, or safety.

Why Monel 400 is a marine workhorse

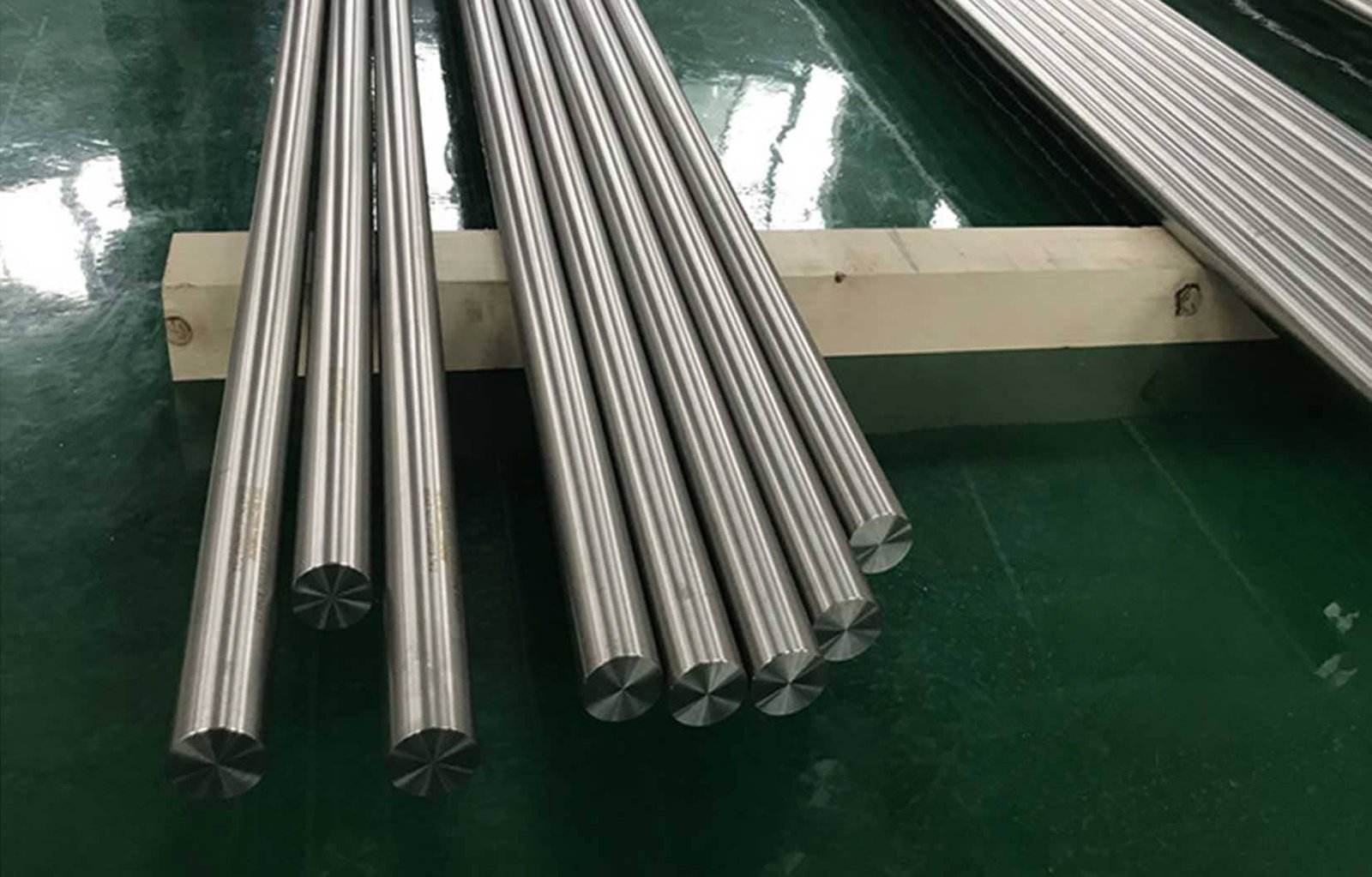

At its core, Monel 400 is a nickel-copper alloy that balances corrosion resistance with toughness and reasonable machinability. That mix matters in seawater, where chloride ions promote pitting and stress-corrosion cracking in less suitable metals. Monel 400 Bars resist those processes better than many stainless steels in continuous seawater exposure. It also welds acceptably and can be strengthened by cold work, which makes it flexible for a range of marine fabrication tasks.

Put simply: when components must withstand salt, flow, and mechanical stress simultaneously, Monel 400 often outlives cheaper options and reduces maintenance headaches.

Where it shines: primary marine applications

Shafts, couplings and rotating parts

Propeller shafts, pump shafts, and couplings see constant immersion, torque, and occasional cavitation. Those are brutal conditions: saltwater erosion plus cyclic loading. Monel 400 round bars are commonly specified for these applications because they resist progressive pitting, maintain toughness under load, and tolerate erosion better than ordinary steels. That translates to longer service life, fewer shaft failures, and reduced dry-docking frequency.

Valves, pump internals and seawater systems

Valves and pump internals are mission-critical in seawater systems — leaks or cracks can shut down entire subsystems. Monel 400’s resistance to chloride stress-corrosion and localized pitting makes it a preferred alloy for valve bodies, seats, and critical pump components in desalination units, ballast systems, and seawater lift pumps. For operators, that reliability reduces unplanned maintenance and improves operational uptime.

Fasteners, studs and through-hull hardware

Fasteners live at the intersection of dissimilar metals, wet/dry cycles, and vibration — all conditions that invite corrosion. Monel 400 fasteners maintain mechanical integrity in marine atmospheres and minimize galvanic attack when paired correctly. Use Monel for through-hull bolts, deck hardware close to splash zones, and any bolting likely to see regular salt exposure.

Heat exchangers, condensers and cooling loops

Seawater cooling systems are unforgiving. Tube pitting and pinhole leaks cripple heat transfer and demand costly tube replacements. Monel 400 used in condenser tubing and exchanger internals preserves heat transfer efficiency by resisting pitting and reducing the frequency of abrasive cleaning. That’s a direct operating-cost advantage in any vessel or plant where seawater is the working fluid.

Subsea and offshore specialty fittings

Offshore and subsea components face high pressures, brine contamination, and biological fouling. Subsea collars, specialty fittings and certain riser accessories need both corrosion resistance and mechanical durability. In situations where retrieval and replacement are hugely expensive, choosing Monel 400 bars for critical subsea parts is a risk-management decision, not a luxury.

Design and fabrication realities — what engineers actually need to know

Materials aren’t judged on lab charts alone. Fabrication, inspection, and maintenance shape real performance.

-

Cold work for strength: Monel 400 is not age-hardening. If your design needs extra strength, specify cold working or appropriate geometric allowances.

-

Welding: Monel welds well when proper filler metals and procedures are used, but qualified welders and documented procedures should be mandatory for critical parts.

-

Machining: It machines better than many high-nickel alloys but still demands correct tooling and speeds to avoid work hardening.

-

Surface finish and crevices: Avoid tight crevices and stagnant zones. Good design for drainage and inspection extends service life.

-

Dissimilar metals: When Monel meets aluminum, steel, or copper, plan for galvanic isolation or sacrificial anodes. Insulating washers or dielectric coatings cut galvanic currents.

Quick spec checklist: require mill test certificates, specify dimensional tolerances for cold-worked bars, mandate qualified welding procedures, and list galvanic mitigation measures on drawings.

Cost calculus — lifecycle thinking, not sticker price

Monel 400 costs more up front than common stainless steels, but the right question is lifecycle cost: what happens if that shaft, valve, or heat-exchanger tube fails? Dry-docking, emergency repairs, lost production, and reputational risk add up quickly. For critical components, Monel often reduces total cost of ownership by cutting downtime, lowering repair frequency, and giving predictable maintenance intervals.

What this really means is: spend more where failures are costly, not where routine inspection and maintenance are sufficient.

Common mistakes and how to avoid them

-

Using Monel everywhere by default. That wastes budget. Reserve it for parts where chloride exposure plus mechanical stress creates real risk.

-

Ignoring fabrication protocols. Unqualified welds and sloppy post-weld treatment undermine the alloy’s advantages.

-

Poor galvanic planning. Pairing Monel with incompatible metals without isolation invites localized corrosion at joints.

-

Skipping inspection access. Hard to inspect parts fail silently. Design for access and non-destructive testing.

You can also read – https://techtrekspot.online/why-metal-roofing-is-the-best-choice-for-parma-oh-homes/

Practical examples — how Monel adds value on a vessel

Imagine a cruise vessel with seawater-cooled chillers. Switching condenser tubes or critical valve internals to Monel 400 reduces the frequency of tube replacements and chemical cleanings. The ship spends less time in a yard and more time earning revenue. Same with commercial fishing or offshore vessels: fewer shaft repairs and more predictable maintenance schedules cut operational headaches.

When to choose alternatives

Monel is excellent in many seawater scenarios, but not every job demands it. For structural hull plating, general fittings, or low-risk hardware where regular coatings and inspections suffice, duplex stainless steels or standard austenitic grades are often more economical. The right approach is hybrid: deploy Monel where its performance matters most, and use lower-cost alloys where risk is tolerable.

Final checklist for procurement teams

-

Define service environment: immersion, splash, or wet/dry cycles.

-

Specify Monel 400 Round Bars with mill test certificates and traceability.

-

Require qualified welding and documented procedures.

-

Include galvanic mitigation and inspection access in drawings.

-

Estimate lifecycle costs, not just material costs.

Conclusion

When specification matters — shafts that won’t pit, valves that hold, heat exchangers that keep cooling — Monel 400 Round Bars are a practical, proven choice. They aren’t cheap, but they buy you reliability. For critical marine components exposed to seawater and chlorides, Monel often reduces downtime, cuts emergency repairs, and lowers total cost of ownership.

By choosing high-quality Monel 400 bars from Nextgen Steel and Alloys you get material traceability, certified test documentation, and timely supply — all essential when shipyards and offshore projects need reliable, certified parts on schedule. For certified Monel 400 round bars and tailored supply options, consider Nextgen Steel and Alloys as your sourcing partner.