Electrical conduit pipes are protective tubes used to route and shield electrical wiring in buildings, industries, and outdoor environments. These conduits are crucial for preventing wire damage, reducing fire risks, and ensuring long-lasting cable performance.

Standards for electrical conduit pipes are more than just guidelines—they’re safety essentials. They dictate the type, size, material, and installation techniques required to meet local building codes, electrical safety regulations, and long-term reliability. Ignoring these standards can lead to system failures, costly repairs, and safety hazards.

In Pakistan, where the electrical infrastructure is evolving rapidly, selecting the right electrical conduit pipes in Pakistan and following the correct installation practices is critical for both residential and commercial projects.

Which Key Standards Govern Electrical Conduit Pipes?

Understanding which standards apply helps installers and buyers make informed decisions. Some of the widely recognized international and local standards include:

1. National Electrical Code (NEC)

The NEC, mainly followed in the U.S. but referenced worldwide, outlines the usage of different types of conduits (EMT, PVC, RMC, etc.) and their installation environments.

2. IEC Standards (International Electrotechnical Commission)

IEC standards, such as IEC 61386, apply to conduit systems for electrical installations globally. They cover mechanical performance, flexibility, impact resistance, and fire behavior.

3. BS EN Standards (British/European Standards)

BS EN 61386-1 and related standards specify requirements for conduit materials, protection levels, and classification in the European region. These are often used in Pakistan for imported or high-end projects.

4. PSI and PEC Standards (Pakistan Specific)

The Pakistan Standards and Quality Control Authority (PSQCA), under PSI and Pakistan Engineering Council (PEC) guidance, also outlines local conduit requirements, especially for government and infrastructure projects.

Knowing and adhering to these standards ensures that the best conduit pipe for electrical wiring in Pakistan complies with performance, safety, and legal requirements.

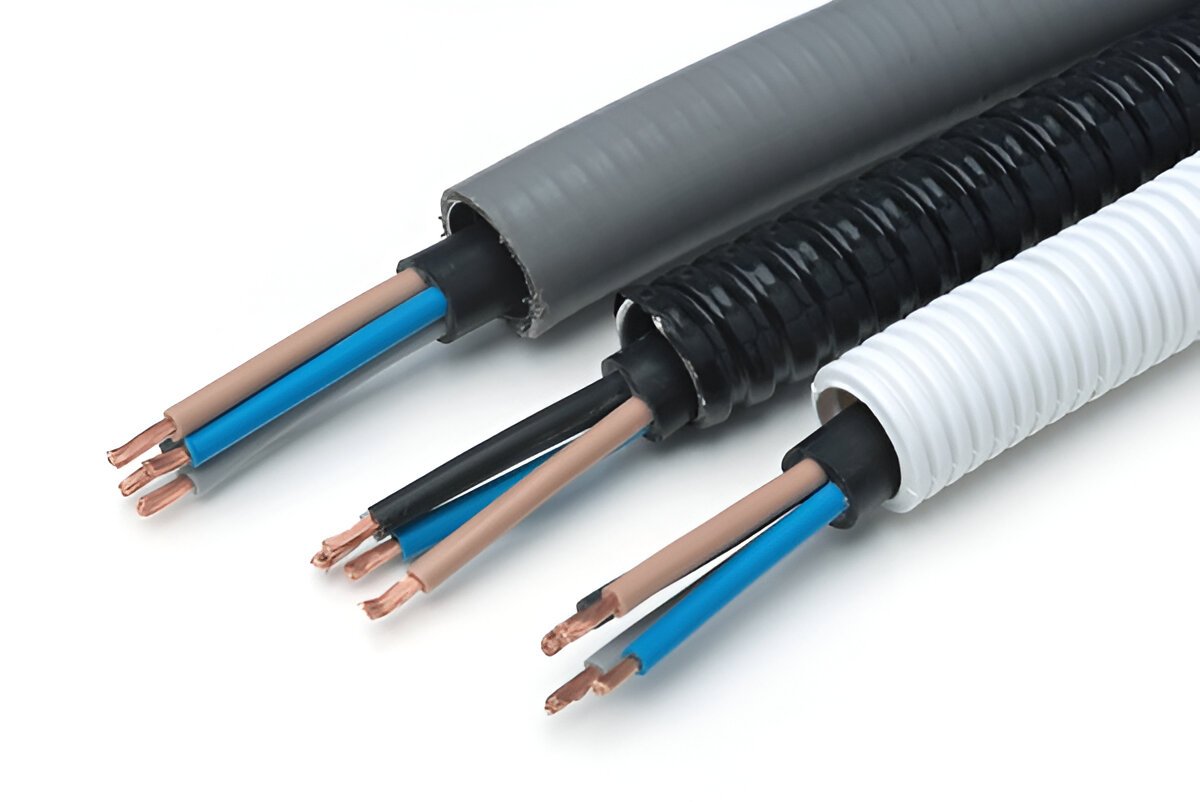

What Types of Electrical Conduit Pipes Comply with These Standards?

Each type of conduit has specific use cases and standards it must follow:

PVC Conduit Pipes

Polyvinyl Chloride (PVC) conduits are lightweight, corrosion-resistant, and ideal for underground or concealed installations. These pipes must meet ASTM D1785 or IEC 61386 for thickness, flame resistance, and mechanical strength.

In Pakistan, the PVC electrical conduit price in Pakistan varies based on thickness (Schedule 40/80), grade, and brand certification. Always look for PSQCA-approved markings when purchasing.

EMT (Electrical Metallic Tubing)

EMT is a thin-walled steel conduit used in indoor applications. NEC requires it to be galvanized and meet specific bending radius and support spacing rules.

Rigid Metal Conduit (RMC)

RMC is thicker and heavier, offering better protection in outdoor or industrial applications. It must comply with corrosion-resistance tests, threading specifications, and wall thickness standards outlined in UL 6 and NEC.

Flexible Conduit

Used in tight or moving areas (e.g., machines), flexible conduits must meet IEC 61386-23, which governs mechanical strength and bending properties.

Each material offers unique benefits and limitations, but compliance with standards ensures safety across all use cases.

What Are the Key Rating Factors for Electrical Conduit Pipes?

To select the right conduit, it’s essential to understand how they are rated and classified:

1. Ingress Protection (IP Rating)

IP ratings classify the resistance of conduits against dust and water. For outdoor use, IP65 or higher is recommended.

2. Fire Resistance

Fire-rated conduit systems slow the spread of flames. Standards such as IEC 60332 define flammability levels. Always choose flame-retardant conduit pipes for high-risk areas.

3. Temperature Ratings

Conduits must withstand the temperature of the environment and the cables they carry. Standards specify minimum and maximum temperature thresholds, usually between -5°C to 60°C for plastic conduits.

4. Impact Resistance

Conduits installed in areas with mechanical stress must pass impact tests (medium, heavy, extra-heavy duty), particularly those installed on floors, walls, or exposed outdoor locations.

Understanding these ratings ensures you’re installing a conduit that will perform safely and reliably in its intended environment.

Where Should You Use Specific Types of Conduit Pipes?

Selecting the right electrical conduit pipe isn’t just about price—it’s about suitability. Here’s how standards guide selection for different locations:

Indoor Applications

PVC and EMT conduits are commonly used indoors due to their affordability and ease of installation. According to NEC and IEC guidelines:

- EMT must be properly grounded.

- PVC must be used with compatible fittings and protected from UV exposure.

- All indoor installations should meet IEC 61386-1 for non-metallic systems.

Outdoor Applications

Outdoor conditions demand robust protection. Use RMC or thick-walled PVC conduit (Schedule 80) with appropriate IP ratings:

- Underground: Use PVC Schedule 40 or 80, conforming to ASTM D1785.

- Exposed: Use RMC or weather-resistant PVC, adhering to IEC 60529 (IP ratings).

In Pakistan’s varying climate, UV-resistant and moisture-sealed pipes are essential. Always verify that products meet local PSI or imported IEC standards before purchase.

What Common Mistakes Should You Avoid During Installation?

Improper installation can cancel out even the highest-quality materials. Some of the most common errors include:

- Using the wrong conduit type for the environment (e.g., indoor pipe outdoors).

- Overfilling the conduit capacity, which causes overheating.

- Skipping expansion joints in long PVC conduit runs.

- Improper bends, violating minimum bend radius standards.

- Not securing conduits within code-defined intervals.

To avoid these mistakes, always refer to NEC Chapter 3 and local building codes. Additionally, when working with electrical conduit pipes in Pakistan, hire certified installers who are familiar with PEC and PSQCA standards.

How to Ensure Compliance with Electrical Conduit Standards?

Following the right steps ensures your installation is safe, legal, and durable:

Step 1: Research Standards Based on Your Location

If you’re in Pakistan, confirm whether local PSI standards apply or if the project follows NEC or IEC guidelines.

Step 2: Choose Verified Materials

Only buy conduit pipes that carry certification labels (PSQCA, UL, IEC, or ISO).

Step 3: Consult a Professional

Involve a certified electrician or contractor to review your conduit layout and recommend compliant materials and fittings.

Step 4: Inspect After Installation

Ensure the installed system is inspected for grounding, sealing, capacity, and support spacing.

Remember: Meeting standards is not optional. It ensures the longevity of the electrical system and prevents hazards like short circuits, cable overheating, and fire.

What Is the Best Conduit Pipe for Electrical Wiring in Pakistan?

Choosing the best conduit pipe for electrical wiring in Pakistan depends on various factors—installation location, environmental conditions, and building type.

For indoor residential setups, PVC conduit pipes are widely favored for their cost-effectiveness and corrosion resistance. Ensure they meet IEC 61386 and ASTM standards.

In outdoor or industrial environments, RMC and heavy-duty Schedule 80 PVC pipes are preferred for their strength and durability.

While many brands offer a variety of options, always prioritize pipes that are fire-retardant, UV-protected, and certified by PSQCA for use in Pakistan.

As a best practice, compare specifications, verify ratings, and consult installation professionals to make a smart investment.

Conclusion: Why Standards Matter More Than Ever

Electrical conduit pipes are the backbone of any safe and efficient electrical wiring system. Whether you’re wiring a home, commercial building, or industrial plant, understanding and following the right standards is critical.

From choosing the right material to verifying IP and fire ratings, every detail plays a role in preventing future issues. Especially in Pakistan, where climatic and regulatory factors vary, adhering to both global and local standards ensures long-term success.

Don’t just settle for any product—choose certified, compliant, and environment-appropriate solutions. Your safety—and your building’s future—depends on it.